Commercial controlled environment agriculture (CEA) allows growers to create an ideal environment catered to plant growth, regardless of geography or outdoor conditions. Growing indoors requires the use of artificial lighting in place of natural light, making your lighting design plan a crucial component of your overall cultivation facility design.

There are many variables to consider when making your lighting selection and layout. Every aspect of your indoor grow will influence this process. Start by answering these questions.

- What will you be growing? (Cannabis? Food Crops? Ornamentals?)

- How much do you intend to produce?

- How much horizontal and vertical space is available to you?

- Do you have any electrical or water resource constraints?

- What is your budget?

This information will help guide the decision making process later on as you begin shopping around for designers and specific lighting fixtures.

Why Does Lighting Design Matter?

Layout Approaches

Whether you are growing cannabis, leafy greens, microgreens, tomatoes, or another indoor crop, your lighting layout will be largely guided by the number of levels you plan to grow on. The number of lights you need will change based on available space and the growing method you choose.

However, commercial cannabis growers have an added layer (no pun intended) of complexity when designing their lighting; they must account for the different growth stages of the plant from cloning to flower.

Single-Tier

The simplest lighting approach is to place your plants directly under an overhead canopy of lights. Lighting selection should be consistent within each room, although with the right controls, you can test various lighting schedules to see what produces the most desirable results.

The simplest lighting approach is to place your plants directly under an overhead canopy of lights. Lighting selection should be consistent within each room, although with the right controls, you can test various lighting schedules to see what produces the most desirable results.

Cannabis plants are usually relocated from room to room as they grow. Naturally, as your plants get bigger, you will be able to fit less plants per light, meaning that veg and flower rooms will require more lights per plant than the nursery. For example, veg rooms usually have 5 to 6 plants per light, and nurseries usually have anywhere from 20 to 100 plants per light. Keep this in mind when calculating room sizing and lighting placements.

Multi-Tier

For vertical farms, lighting designs must account for growing in multiple tiers. This is achieved by mounting lights above each layer of the grow racks.

For vertical farms, lighting designs must account for growing in multiple tiers. This is achieved by mounting lights above each layer of the grow racks.

Vertical farmers do not typically have the freedom to choose HID lighting as it requires a much greater height above the canopy than LED fixtures, which typically only require a height of 1ft above the canopy. But some growers have claimed to use their LEDs to achieve unique results, such as changing the color of their produce or boosting vitamin C levels, all by simply altering their lighting recipes.

Start Designing

As you can see, there is a science to lighting design for commercial grow rooms. There is a laundry list of variables to take into consideration when making your lighting selection and preparing a layout. Luckily, you aren’t expected to quit your day job to become a lighting expert.

Choosing the right lighting vendor will provide you with all the resources you need to make your lighting design a success. Surna Cultivation Technologies has been providing solutions to indoor growers for over 15 years and have served over 800 cultivators with over 200 of them being large, commercial projects. We’ve partnered with BVV to bring you high quality lighting solutions built for indoor agriculture.

Here’s how our team can help:

- Discuss your goals, budget, and other variables key to the design process

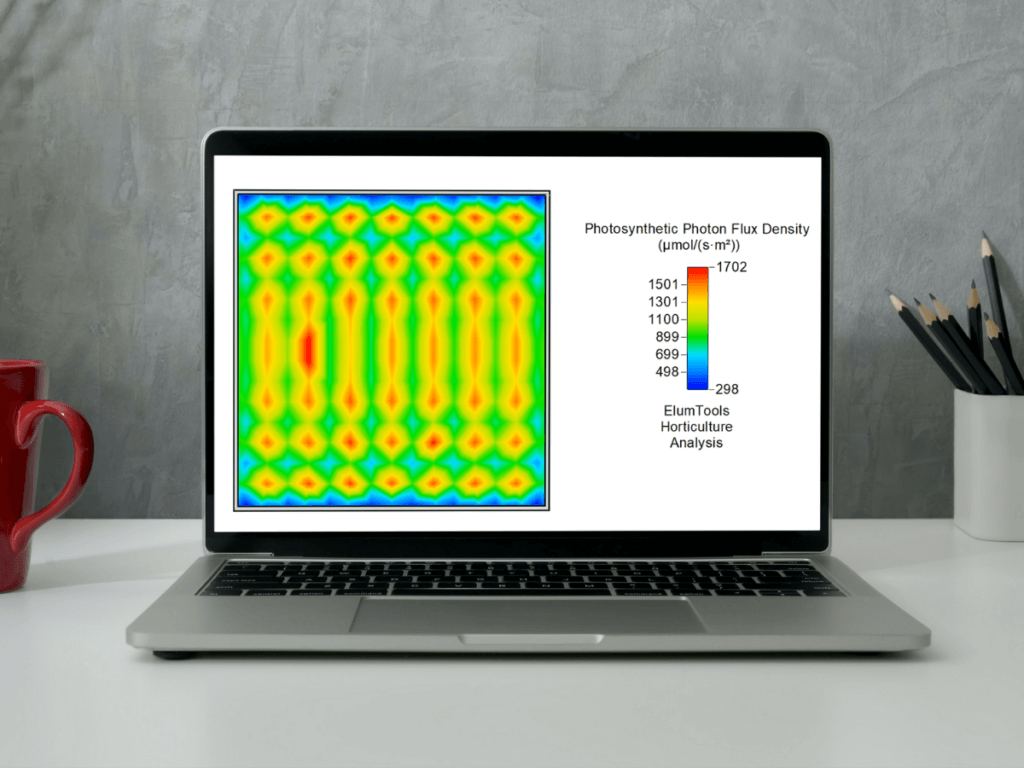

- Provide layout proposals for each room that include PPFD models

- Offer LED lighting fixtures that feature the lowest cost per micromole backed by an industry-leading warranty

- Assist you with applying for rebate programs or necessary energy upgrades

- Provide other products and services you may need: architectural design, licensed MEP engineering, HVAC systems, benches and racks, air sanitization equipment, and more