EXPERT ENGINEERING BY LICENSED PE’S

Our in-house design and engineering capabilities empower us to deliver solutions that lead to healthier crops, improved energy efficiency, and superior reliability. With our help, your growing operation will have an optimized environmental control system that does right by you and your plants.

Unlike in a traditional HVAC setting, indoor cultivation facilities require climate control solutions that attend to the unique needs of the plant. In order to achieve the most precise and efficient grow room climate, choose engineers who have a solid understanding of variables unique to controlled environment agriculture such as lighting, watering schedules, humidity, plant transpiration rates, airflow, odor control, regulation requirements, and more. Our specialized team of licensed MEP engineers provide the sophisticated approach to indoor agriculture you’ve been looking for.

After architects complete the floor plans, engineers must design the nuts and bolts of the facility; how will you heat, cool and dehumidify the cultivation spaces? Do you need an electrical service upgrade? Can your plumbing systems handle fresh and waste water effectively? Don’t worry, we’ve got you covered, and we can provide fully-stamped construction documents.

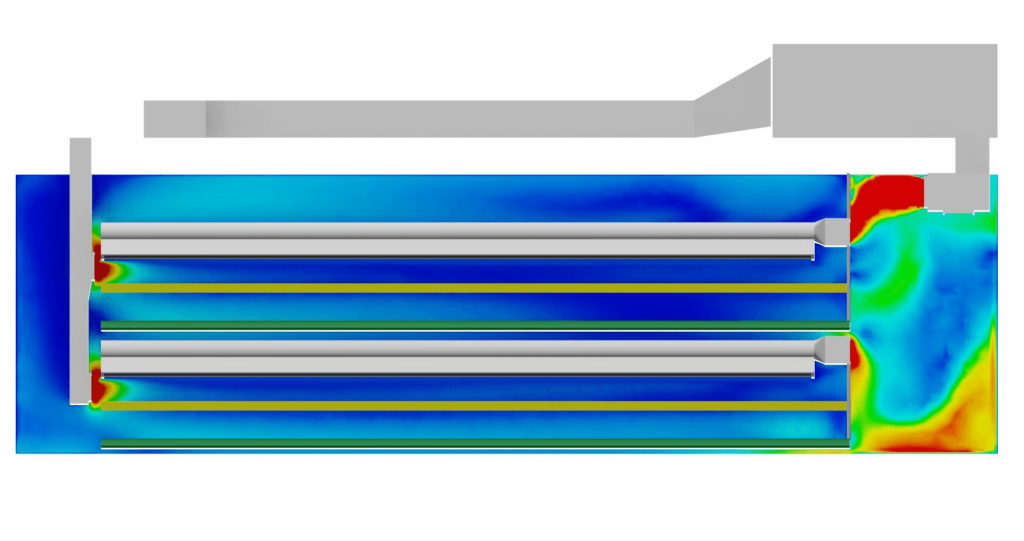

Computational Fluid Dynamic (CFD) Modeling is an advanced 3D tool that engineers can use to more accurately predict the distribution of temperature, humidity, and CO2 throughout the grow space. Incorporating CFD analysis into your facility design helps fine-tune your system before purchasing and installing equipment. We offer CFD modeling for clients who are looking for a highly-optimized grow room environment.

3 Easy Steps to Get Growing

Contact Us

We’ll have a brief discussion about your facility and the goals you are looking to achieve with it.

Review Your Options

We’ll clearly articulate the cultivation system options available to you to help make your decision process easier.

Receive a Solution

You’ll receive a customized solution to meet your specific goals.

Among the many benefits of choosing Surna Engineers are:

Licensed mechanical, electrical,

and plumbing (MEP) engineering

Fully-stamped construction

documents in the U.S. & Canada

Experienced PE’s who specialize

in CEA environments

Project management and

support from design to buildout

Solid Engineering, load calcs are always on spot on.

I've had very good experiences collaborating with Surna as being both the equipment supplier and Engineer of Record on a large cultivation project. We worked through a number of issues that saved the Owner both time and money.

Take a look into a working facility!

Take a tour of this New Mexico cultivation facility where Surna’s engineering and equipment helped co- owners Jeff and Drew significantly reduce their energy consumption and maintain a precise climate.

Recommended Reading

10 Questions to Consider When Vetting Design Firms

(WEBINAR) Managing Temperature And Humidity In Indoor Farms

(WEBINAR) CEA Facility Design From A to Z

Contact Us

Ready to get started or learn more about how we can help your facility succeed? Fill out the form and a company representative will be in touch.