Indoor cannabis grow room layouts are designed to follow the plant growth cycle. While the timeline varies depending on the strain and other factors (like lighting schedules, nutrients, climate parameters, etc.), cannabis grows in stages:

- Germination (between 1-7 days)

- Seed (between 2-3 weeks)

- Veg and Pre-flower (between 2-10 weeks)

- Flower (between 6-8 weeks)

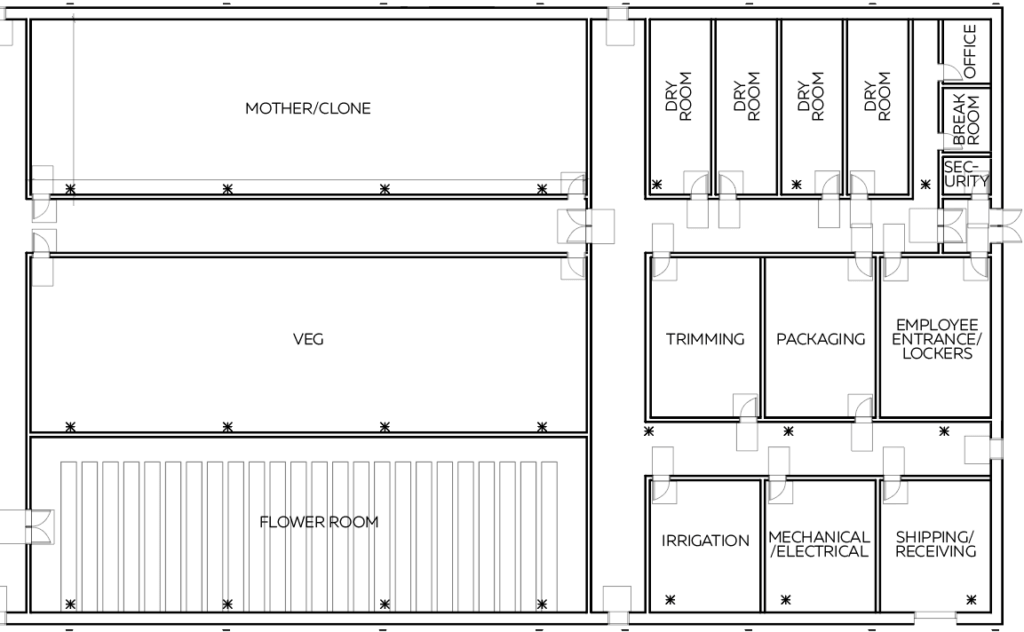

Commercial Grow Facility Design

Most operations designate rooms for each stage of growth, but every setup is unique. A typical commercial scale cannabis facility will include the following rooms:

- Nursery/Propagation/Clone Room – cuttings are used to produce young clones

- Veg Room – seedlings are transplanted into larger containers so they can grow and mature

- Flower Room – mature plants flower and are prepared for harvest

- Dry Room – trimmings are hung to dry before being packaged for sale

- Irrigation and mechanical rooms – large grow equipment is accessible for irrigation, fertigation, water reclamation, and HVAC.

- Personnel Areas – non-grow spaces like bathrooms, break rooms, locker rooms, packaging and shipping spaces, security offices, and main offices.

Cannabis Vegetative Stage

The vegetative stage, often shortened to “veg,” is part of the cannabis plant growth cycle. During veg, young plants are given a larger container to grow in so that it can become well established and prepared to flower.

For best results, introduce them to increased lighting and provide lower relative humidity (RH) than in propagation but more than they will get in flower.

What is a Veg Room?

In indoor cannabis cultivation, the “veg” room (sometimes referred to as pre-flower) is where rooted clones or seedlings from the nursery are transferred to continue to mature before being turned over to flowering for harvest.

In this vegetative growth phase, plants are slowly weaned off the babying they received in their earlier rooting phase and hardened off to become accustomed to more powerful light and dryer conditions required to maximize yields in flower.

Plants do most of their elongation in the vegetative growth phase, where they will also gain mass and bulk. However, they will continue to gain height and size during the first few weeks of the flowering phase (or 12/12 photoperiod) before shifting their energy to producing flower.

The veg stage is critical to the size and quality of your final harvest. It’s an opportunity to both give your plants the best possible start before moving to flower, and to cull weaker specimens instead of taking up valuable flowering space with a plant that might not perform as well as its peers.

How to Set Up a Veg Room

In a perfect world, each veg room is dedicated to no more than 3-4 flower rooms. This way, you will only need to manage veg plants for one flower room at any given time. However, many cultivators will supply multiple flowering rooms from the same vegetative room on a rotation, which means that the veg room should have sections dedicated to the flower room(s) that section is serving.

Space Planning

Carefully consider the allocation of space in your veg rooms. New cultivators commonly fail to allocate sufficient square footage. A good rule of thumb is to assume that you’ll need approximately 1 square foot of vegetative canopy for every 4 square feet of flowering canopy. So, if you have 4 flowering rooms with 1,000 square feet of canopy each (4,000 square feet of flower space total), you’ll likely need something in the neighborhood of 1,000 total square feet of vegetative canopy to supply those rooms.

Conserve Space with Vertical Racks

As plants are generally smaller and shorter in veg than they are in flower, they don’t require trellising. Rather than scaling horizontally, veg rooms present a great opportunity for you to conserve square footage by utilizing your vertical space.

Set up multi-tier grow racks to maximize floor space. Work with your racking supplier to help you determine the best layout. Your lighting supplier should also help you choose a fixture that best complements the fixture layout. And consult with your HVAC designer to ensure you’re getting good, homogenized airflow through the plant canopy.

Lighting

Whatever lighting decisions you make, select fixtures that are optimized for the vegetative growth phase. Growers have different lighting technology preferences, but the cannabis industry is increasingly adopting LED technology in both vegetative and flowering phases of growth.

What is the Best Light to Veg Cannabis?

Not all horticultural LEDs are created equal. They vary widely in cost, efficiency, spectrum, and warranty. Additionally, the optimal spectrum for maximizing vegetative growth is different from the optimal spectrum for maximizing flowering growth, as is the optimal PPFD. Work with a lighting company that can help guide your selections by providing light mapping and detailed spectrum information about the fixture they recommend.

Light Wattage

Similarly, it’s generally safe to assume that you’ll need around 25% of your total light wattage in the flower room to support vegetative growth. So, if there are 50,000 watts in the flower room(s), your total vegetative wattage will probably land around 12,500 watts. This is just a general guide, and you should consult with your lighting manufacturer to determine the ideal layout for the PPFD you are targeting in veg.

Lighting Schedules

Similar to when plants are in the nursey, a light cycle of 18 hours on and 6 hours off is the traditional approach for the veg phase. This mimics the natural light cycles a cannabis plant would receive outdoors during this stage of growth which keeps the plants from generating flowers.

Young plants may stress under strong lighting for 18 straight hours a day, especially in the first several days after transplant before they’ve become accustomed to the stronger light.

In this case, some cultivators may opt to dim their lighting, or reduce the number of fixtures, until the plants become accustomed to the new lighting conditions and the root systems are able to provide sufficient moisture to compensate for the change in vapor pressure deficit (VPD).

Some cultivators opt to keep light at full power and instead alternate the light and dark cycle to 6 hours on and 2 hours off. This doesn’t trigger flowering, as the 12-hour dark photoperiod is what initiates the flowering stage in the plant and may allow you to keep light at full intensity without over-stressing new plants.

Climate

Optimal growing conditions in the veg rooms will be slightly dryer than in the clone/seedling stage, but not as dry as in the flowering stage. Keep in mind that the root systems aren’t yet well developed, and with more powerful lights and lower humidity, transpiration of moisture will increase, and the root zone will need time to develop.

What’s the Best Temperature and Humidity for Vegging Cannabis?

A temperature in the mid 70’s to low 80’s (F), and a humidity in the 60-70% range, is ideal for vegetative growth.

If you have space dedicated to veg, and the luxury of a flexible mechanical (HVAC) design, you can start the vegetative stage of growth at a slightly higher humidity and gradually step it down in 5% increments every few days. This gives the plant plenty of time to adjust to changing conditions and prepares it for the even dryer conditions in flower, which most cultivators target at 50-60% RH.

If you plan to do this, make sure your mechanical engineer understands both your climate goals and your irrigation volume so they can design a system that meets these needs. In some cases, the watering volume in early veg is too low to keep humidity high enough, and humidification may be required in parallel with dehumidification for later stage vegetative growth, when watering rates are higher and humidity targets are lower.

Transplanting and Moving Plants

When nursery plants are initially transferred to veg, they are up-planted during the initial transfer. Then, depending on the cultivation methodology, they can be up-planted one to two additional times prior to being transferred to flower.

Some growers choose to do this only once to avoid the additional labor associated with repotting, but this can result in excessive water and nutrient waste. Pay special attention to your irrigation practices if this is the case. Correctly sizing the container usually yields the most effective result. This assumes you are using pots and a coco or soil medium. If you are cultivating hydroponically or aeroponically, this is a slightly different process.

When up-planting in a soil/soilless medium, break up the root ball. While it may seem counter-intuitive, this is very important for new root growth. Taking care not to break roots or stress the root ball, gently break up the dirt and roots with your hands so that the root system no longer maintains the shape of the previous container. This is also a good time to introduce mycorrhizal fungi and bacteria to the root zone to promote rapid healthy growth.

Culling: Nursery to Veg

Each time you up-plant, take the opportunity to cull plants which may not be as healthy or productive as others. Allow for 10-25% more plants to be moved from nursery to veg than will ultimately be flowered. This gives you room to cull plants that may not be performing. As you dial in your cultivation methodologies, you may be able to reduce that initial overage.

Culling: Veg to Flower

Perform a final culling just before plants are moved to flower. At this point, only keep the healthiest, hardiest plants and discard anything that remains. If you are doing a great job, then you will be throwing away healthy plants (which is always the goal because you have consistently kept more than were needed for the next stage of growth).

All plants that move onto the flower room should be healthy and robust, showing no signs of deficiency/toxicity or pest/bacterial/fungal infestation. The flowering phase puts a lot of stress on the plant, both because of the intensity of light and the amount of energy the plant uses to produce flower. You want to make sure they start this phase of growth with the healthiest possible foundation.

Ready to start planning your veg room design?

Surna Cultivation Technologies can provide everything you need to bring your operation to life including architectural design and floor plans, MEP engineering, benches and grow racks, LED lights, and more.

Contact us today to discuss your goals.