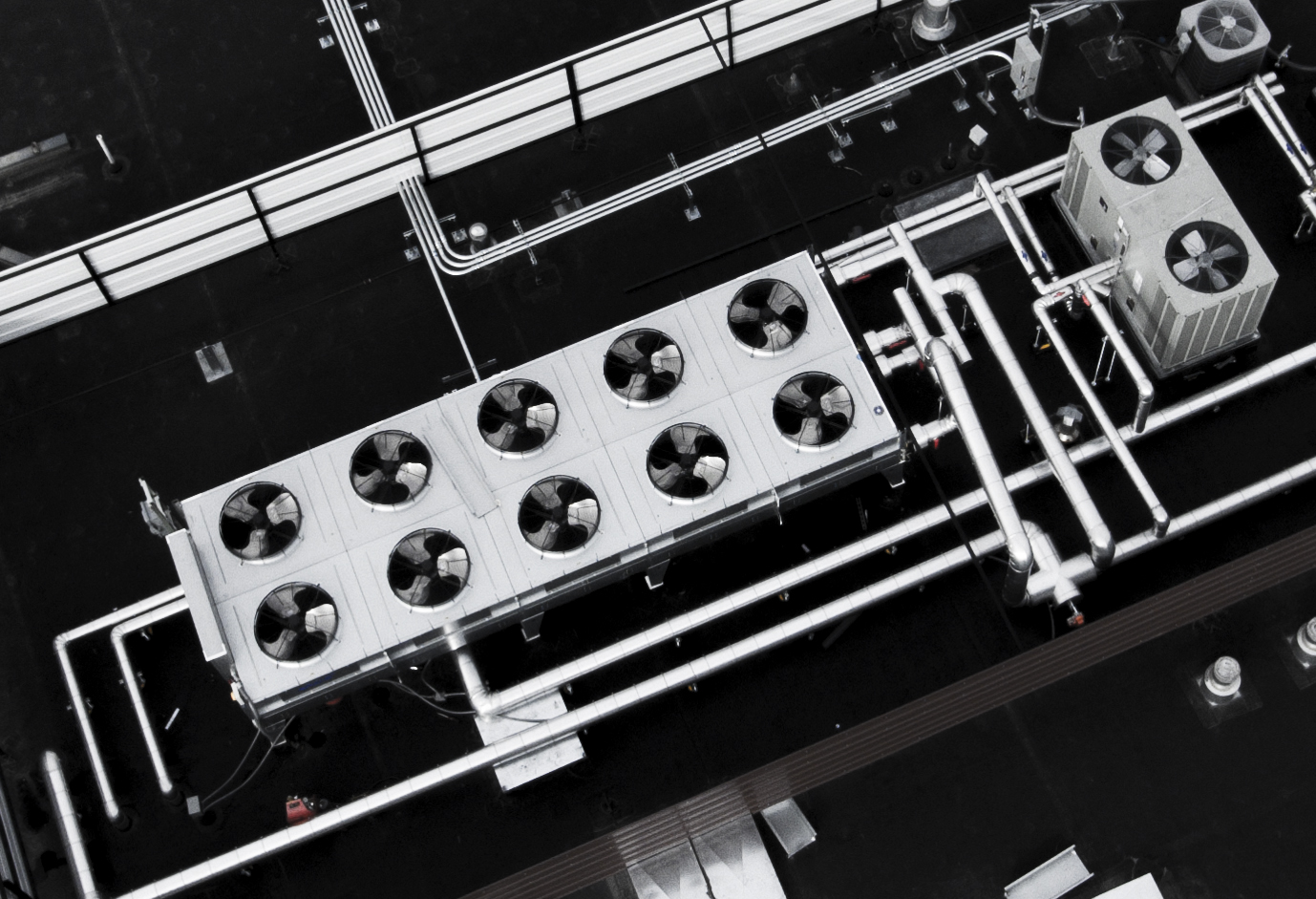

The Argument for Indoor or Sealed Greenhouse Cultivation

The truth is, there is a strong business case to be made for cultivating in controlled environments. And in the near future, as renewable energy options increase and climate change continues to impact weather patterns, there will be a strong sustainability case to be made as well.