Reasons you aren’t meeting setpoints (HVAC/D)

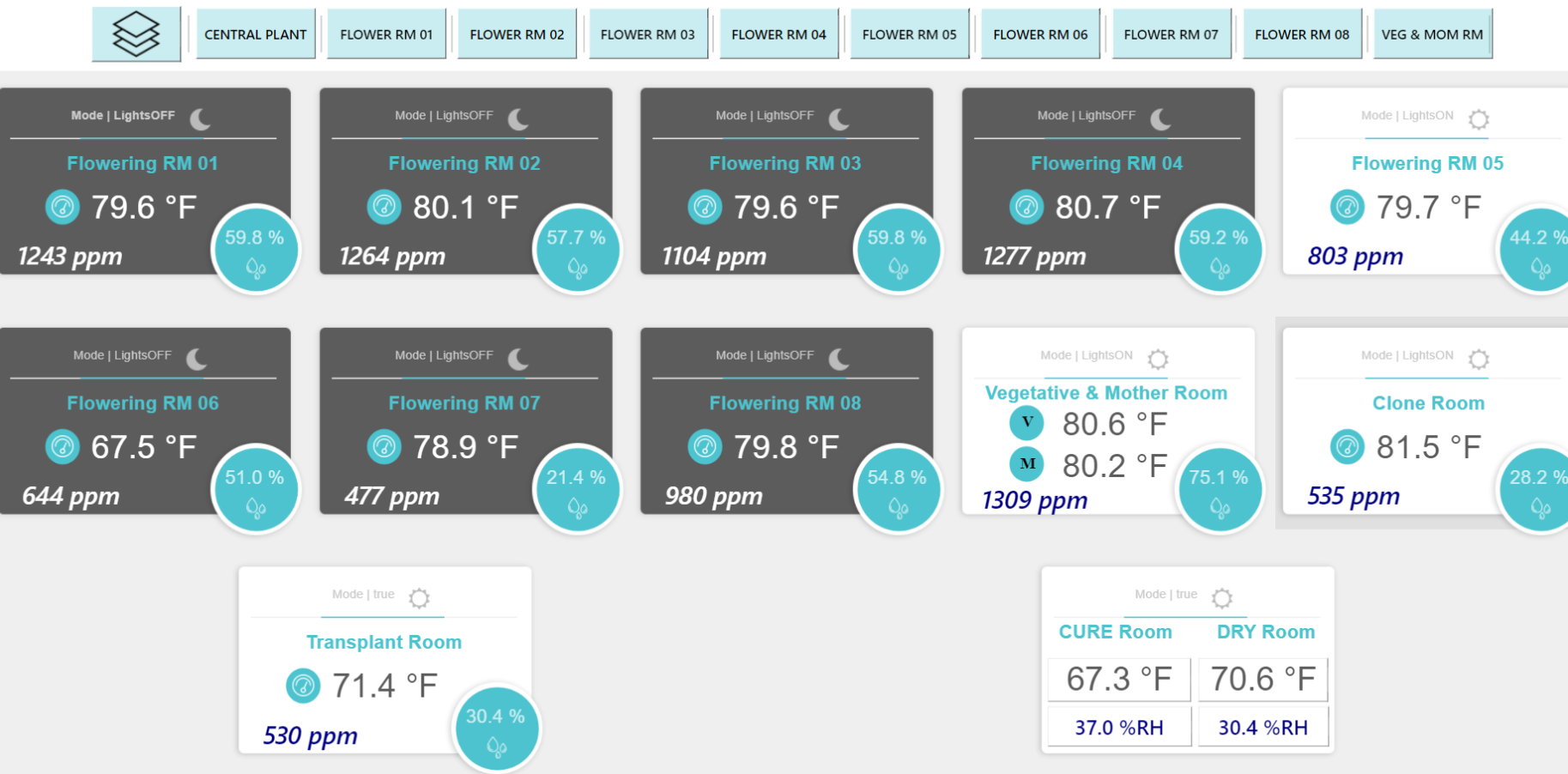

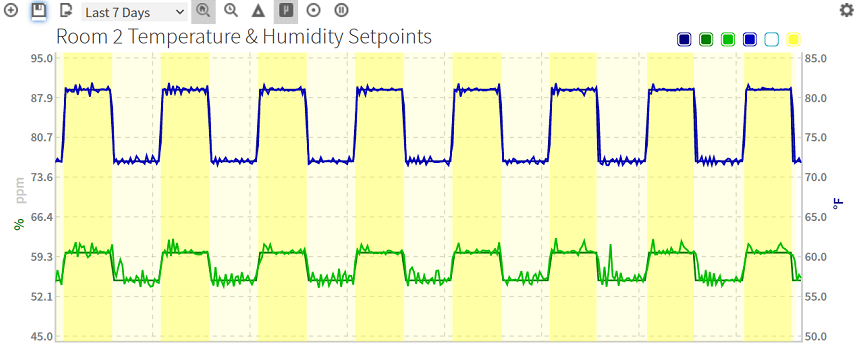

Cultivators often face challenges in maintaining HVAC/D setpoints, with issues ranging from humidity to equipment failures. Both commercial and home growers recognize the importance of a reliable system for optimal cannabis and greens production. Identifying common failures and implementing best practices ensures consistent climate control in grow spaces.