What is Indoor Agriculture and Vertical Farming?

What is indoor agriculture? While cannabis cultivators have already been growing indoors for years, vertical farms could be the future of agriculture on an even larger scale.

What is indoor agriculture? While cannabis cultivators have already been growing indoors for years, vertical farms could be the future of agriculture on an even larger scale.

Equipment malfunctions, nuances of specific geographies, unexpected power limitations, cultivar inputs that need tweaking. These are just some examples of issues that may not be fully apparent until the facility is in operation, and anticipating the possibility ensures that you’ll be well prepared to address them.

Anyone who has ever built a cultivation facility can confirm that it’s a long and stressful process. And for those who haven’t? Hear us now: It’s a long and stressful process and it’s important to have realistic expectations about timelines during the pre-planning stages.

The truth is, there is a strong business case to be made for cultivating in controlled environments. And in the near future, as renewable energy options increase and climate change continues to impact weather patterns, there will be a strong sustainability case to be made as well.

The obvious benefit to tiered applications is the ability to increase canopy square footage without additional building square footage. Although there are some drawbacks to multi-tier growing, there can also be great reward, and so we’re seeing more and more of our clients choose to go this route in their facilities.

Apart from our deep expertise and value in engineering design, where we can provide equal value to our clients is in the design-build HVAC model. The complexity of systems in cannabis facilities usually necessitates a well-coordinated effort, with an experienced, well-qualified central party taking responsibility for the mechanical system from concept to design to equipment and integration.

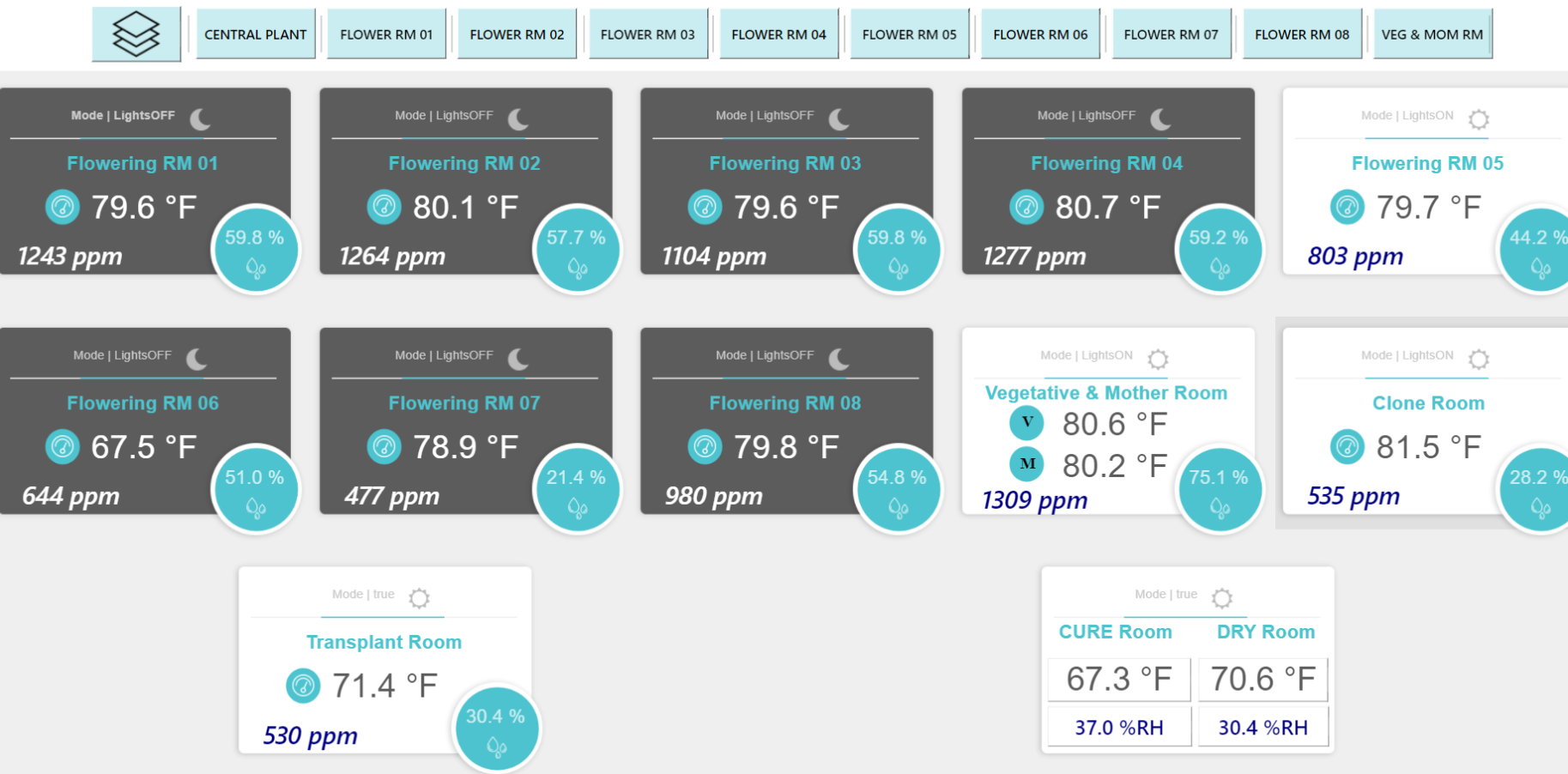

Most cannabis industry cultivators think of “controls” as the dashboard where they can see their room parameters and adjust photoperiods or temperature setpoints, and a lot of folks make their decisions around controls based solely on that user interface. This is an important part of the toolkit but is really the least critical piece to a controls system’s functionality.

Understanding how different technologies are best applied in various circumstances is what led us to pursue all different types of technologies that we can offer to our clients. Our line of custom air handlers, which can be applied in either chilled water or DX (refrigerant based) applications, resulted from those efforts.

When given the opportunity to work with some of our design and construction peers to put together a design/build resource for the industry, we jumped at it. The result was “Build Your Grow,” which you can read here. However, we thought it would also be helpful to do a quick recap of the top takeaways for a quick read.

Surna has evolved into a full-scale MEP design firm, manufacturer and provider of HVAC equipment, controls company, and implementer of all components in cannabis cultivation. We provide MEP drawings, support permitting, and coordinate with other design disciplines as needed.