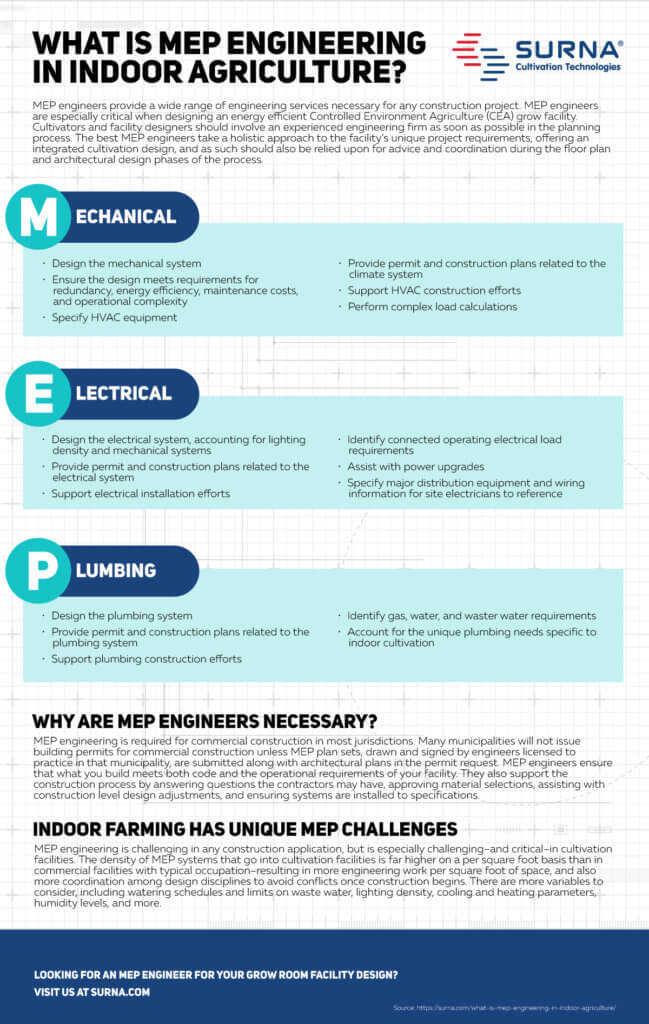

MEP engineers provide a wide range of engineering services necessary for any construction project. MEP engineers are especially critical when designing an energy efficient Controlled Environment Agriculture (CEA) grow facility. Cultivators and facility designers should involve an experienced engineering firm as soon as possible in the planning process. The best MEP engineers take a holistic approach to the facility’s unique project requirements, offering an integrated cultivation design, and as such should also be relied upon for advice and coordination during the floor plan and architectural design phases of the process.

Here are some important things to know about MEP engineering in indoor farming:

- Defining the M-E-P in MEP Engineering

- Benefits of MEP Engineering

- Challenges of MEP Engineering

- Choosing a Specialized Engineering Firm

Learn More: Licensed MEP Engineering

Defining the M-E-P in MEP Engineering

Mechanical, Electrical, and Plumbing (MEP) engineering indicates the primary range of disciplines in which indoor agriculture facilities require engineering and design.

Mechanical engineers are responsible for designing, specifying equipment, providing permit and construction plans, and supporting construction efforts associated with Heating, Ventilation, and Air Conditioning (HVAC) systems, or in commercial cannabis and food cultivation applications, Heating, Ventilation, Air Conditioning, and Dehumidification (HVACD) systems. The mechanical design team should perform the complex load calculations necessary to ensure the climate control system is appropriately sized and specified to manage the variable and often extreme temperature and humidity loading associated with cultivation operations. At the same time, they must also ensure the mechanical design meets owner requirements around redundancy, energy efficiency, maintenance costs, and operational complexity.

Electrical engineers are responsible for designing, providing permit and construction documents, and supporting construction efforts associated with the electrical systems in cultivation facilities. This includes identification of connected and operating electrical load requirements and assistance with ordering power (or power upgrades) from the utility or CHP provider, specification of major distribution equipment, and relevant wiring information for the site’s electricians to reference during construction. The density of lighting and mechanical systems in cultivation operations make the quality of electrical engineering, and coordination with the mechanical engineer in particular, especially critical in cultivation facilities.

Plumbing engineers are responsible for designing, providing permit and construction documents, and supporting construction efforts associated with water and gas piping systems in cultivation facilities. This includes identifying gas, water, and waste water requirements in cultivation facilities and ensuring the piping design supports those requirements. Plumbing engineers do not, however, usually get involved in waste water management after waste water leaves the building, which is typically handled by a civil engineer depending on the requirements of the municipality.

Read More: Engineering Greatness: Meet Kenneth Loshelder, PE

Benefits of MEP Engineering

In most jurisdictions, MEP engineering is an absolute requirement for commercial construction. Most municipalities will not issue building permits for commercial construction unless MEP plan sets, drawn and signed by engineers licensed to practice in that municipality, are submitted along with architectural plans in the permit request.

MEP engineers ensure that what you build meets both code and the operational requirements of your facility. They do detailed calculations to identify the requirements of the systems in the facility to ensure that they do what the owners need them to do, and that they do it safely and in accordance to building codes.

In addition to satisfying municipality requirements for permitting, the drawings that MEP engineers produce provide the construction roadmap for contractors. Just as the architectural plans tell construction professionals what to build, so do the MEP plans tell the electricians, HVAC professionals, and plumbers what to install, and how to install it. They also support the construction process by answering questions the contractors may have, approving material selections, assisting with construction level design adjustments, and ensuring systems are installed to specifications.

Even in the very rare cases where a municipality may not require a building permit, cultivators are well served to engage with qualified and experienced mechanical, electrical and plumbing engineers to ensure that their building adequately meets their needs, and continues to for the life of the facility.

Challenges of MEP Engineering

MEP engineering is challenging in any construction application, but is especially challenging–and critical–in cultivation facilities.

First, the requirements for each component of MEP design are significantly more robust in commercial grow facilities than the requirements in an office building or storefront. This means that the density of MEP systems that go into cultivation facilities is far higher on a per square foot basis than in commercial facilities with typical occupation–resulting in more engineering work per square foot of space, and also more coordination among design disciplines to avoid conflicts once construction begins.

Indoor farms require far more equipment than facilities designed primarily for human occupation, which results in spatial and structural challenges. Finding a place for all of the equipment needed both inside and outside the building, or on the rooftop, requires experience and a thorough understanding of all the different solutions available to meet those challenges affordably.

From a mechanical standpoint, designing to meet every need of the facility–from budget, to biosecurity, to odor control, to operations and energy efficiency–requires deep experience. Further, the load calculations themselves and technology design decisions require specialized expertise and direct experience with a wide range of HVAC and HVACD technologies.

Municipalities often place limits on waste water volume, or regulate its content, resulting in unique challenges for plumbing engineers to address. Electrical engineers are often particularly constrained by the availability of power, being tasked with limiting the size of power upgrades or finding creative ways to get the most possible output from a limited amount of electrical infrastructure. Mechanical engineers are often involved in those discussions as well, as the climate system makes up such a substantial part of the overall facility power requirements.

Solid Engineering, load calcs are always on spot on.

I've had very good experiences collaborating with Surna as being both the equipment supplier and Engineer of Record on a large cultivation project. We worked through a number of issues that saved the Owner both time and money.

Choosing a Specialized Engineering Firm

To fully capitalize on the benefits of MEP engineering in cultivation facilities, select engineers with meaningful experience designing cultivation facilities. Mechanical engineers must understand every stage of plant maturity, every change to irrigation volumes and parameters, and exactly how and when lighting converts to heat in order to correctly manage temperature and humidity. They must also address biosecurity and odor control, while keeping operating costs, maintenance requirements, and operational complexity top of mind during the design process to ensure seamless operation. And all of these things must be included in a design that also fits the owner’s budget.

According to the Resource Innovation Institute, mechanical systems can account for as much as half of a grow facility’s energy usage. However, appropriate cultivation system design and critical parameter selection for efficiency by the right design and engineering firm can have a major impact on efficiency and easily reduce operating costs by as much as one-third.

See how Durango Cannabis Company was able to reduce its water bill to $30/month through water reclamation using their HVACD and irrigation systems:

Electrical engineers must understand not just each piece of electrical equipment in the space, but how and when it’s operated. Plumbing engineers need to understand exactly what the irrigation process looks like, how much water is needed, and how much waste to account for.

While any appropriately licensed MEP firm can develop and stamp plans for a cultivation facility, pay special attention to the applied experience of the engineers being considered. Choosing designers who lack direct and significant experience in designing cultivation facilities will likely result in excessive operating costs, excessive construction costs, delays in time to market, or failures to consider every aspect of the facility’s operating requirements during the design process, which can wreak havoc once the facility is in operation. This usually results not from failure in engineering itself, but rather failure to ask the right questions to ensure that each of the facility’s needs is being adequately addressed with the design.

Need to Talk to An Experienced MEP Engineer? Contact Us.

Keep in mind that MEP engineering is usually performed by several engineers working in concert on the same project. You may choose to select one firm for all three disciplines, or you may choose to select different firms for each discipline. No matter who you choose, make sure you ask the right questions about their experience, and request client referrals when possible. Above all, connect your architectural and engineering team early in the process, and ensure that they collaborate often. No decision in cultivation facility design should be made in a vacuum.