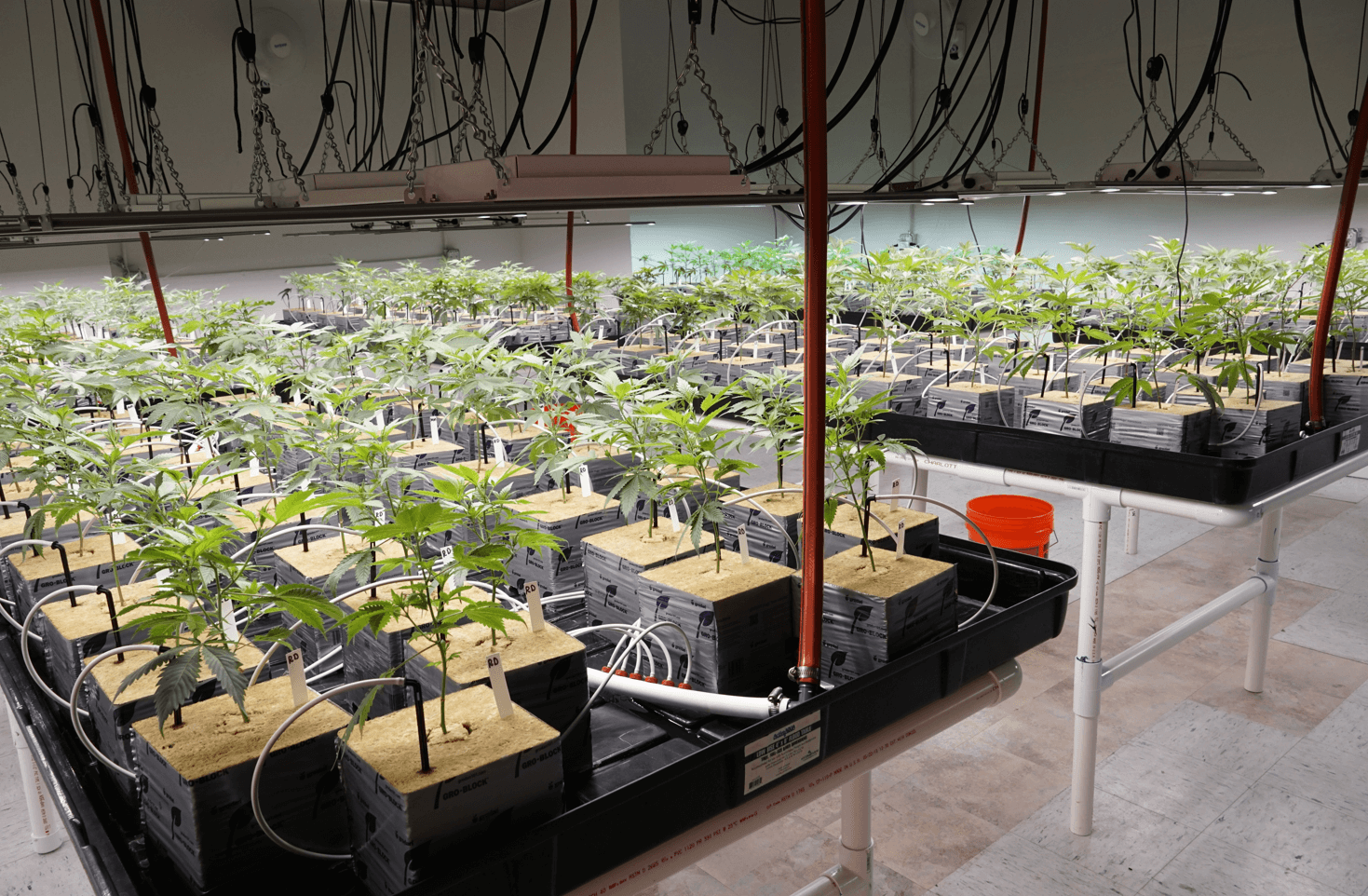

The nursery is where it all begins. Just like the name implies, baby plants are nursed into teenage plants so they can be moved to the vegetative rooms. The way you start a plant is up to you – from seeds or clones or tissue culture– but whatever method you choose, the ultimate goal of the nursery room is to force fast, robust growth and root development without causing damage.

Seedling Stage

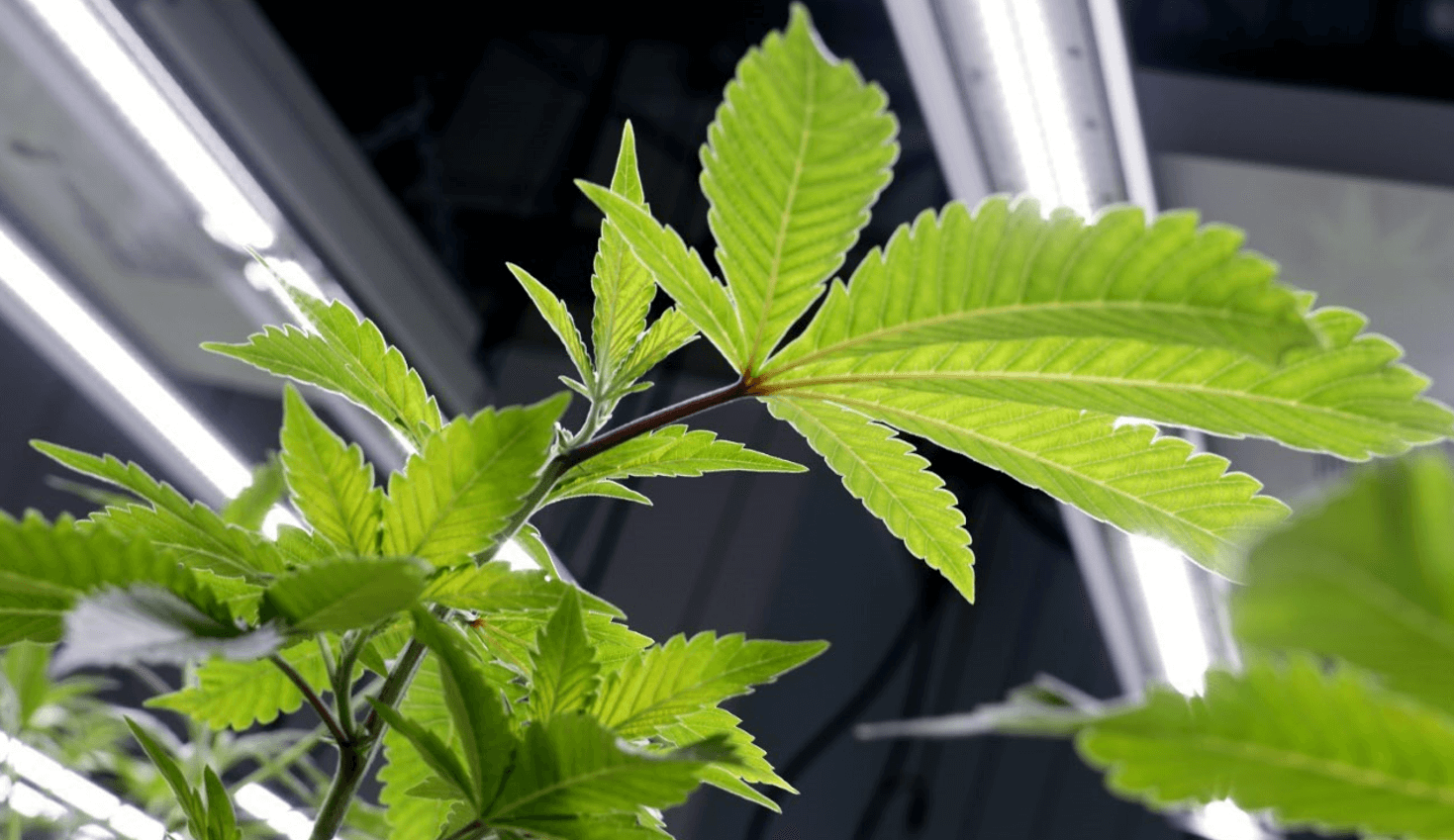

While there are several methods for starting cannabis plants, all new growth shares the vulnerability of a limited root system. Mature plants uptake water and nutrients through their roots, but baby plants are still hard at work growing those roots in the first place. Because their leaves and roots are not yet developed, seedlings are sensitive to under-watering, over-watering, disease, transpiration inconsistencies, and light burn.

Cannabis leaves are identifiable by their 3-13 distinct points. A plant is typically considered ready to be moved to veg once its leaves have developed 5-7 points.

What is a Nursery?

Depending on the method you choose for reproducing plants, the nursery room can go by various names. For example, if you take trimmings from a mother plant to produce clones, the nursery is usually referred to as the “clone room.” Other cultivators refer to their nurseries as propagation rooms.

Cannabis nurseries can be established as their own businesses entirely, with the goal of the operation being to sell seeds, seedlings, and clones to other cultivation operators. Many commercial grows, however, opt to grow their own crops from seed to sale. In these cases, a nursery room is a space dedicated to growing baby plants until they are ready to be transferred to the next phase of the growth cycle.

Starting Cannabis Plants

There are many ways to grow plants from seeds or clones into mature plants ready for the vegetative rooms, including:

- Clone machines

- Tissue culture

- Organic and rockwool plugs

- Organic mats with a humidity dome and temp controlled root zone heat mat

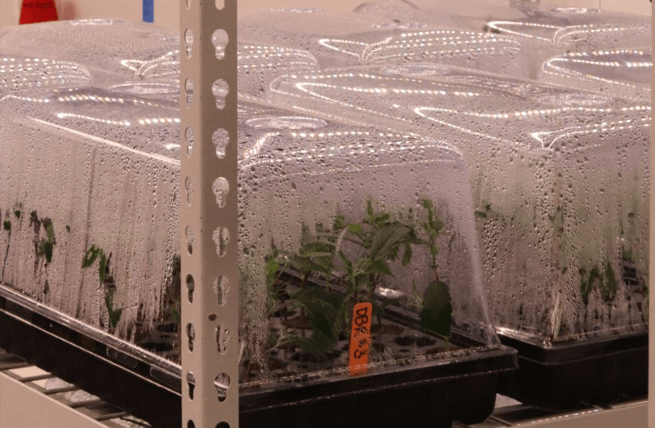

Using humidity domes can help protect the plants and removes worry about improper humidity levels in the nursery room. When using humidity domes, at least one vent should be open at all times to avoid building up too much humidity. If clones are rooted in extremely high humidity, they will need to be hardened off in order to remove the domes without severe wilt.

Never spray seedlings or clones while in the humidity dome. The plant material is susceptible to rotting wherever water drops sit for extended periods of time without being able to dry.

If you are not using humidity domes, special attention will need to be made at the mechanical design phase of the project to ensure that the humidity is properly maintained in the nursery. Nursery rooms are exactly opposite flower rooms in terms of humidity—the baby plants like a very humid environment to minimize transpiration while they build up a root system, and there is very little irrigation volume to maintain higher humidity. In this case, humidification of the space will be key, in conjunction with temperature control, air filtration or sterilization, and a thoughtful airflow designed to ensure homogeneity without damaging the tender new plants. All of these considerations should be part of the mechanical (HVACD) designer’s scope.

How to Set Up a Cannabis Nursery

Though recommended, the nursery does not need to actually be located in its own room. In general, 2-5% of the cultivation facility grow space is usually dedicated to the nursery. In smaller cultivation centers, the nursery can be located inside a vegetative room as long as there is adequate space between the nursery shelving units and the lighting used for vegetative plants. Typically, eight feet is enough to separate nursery plants from vegetative plant lights; any closer and the more intense light used in vegetative rooms can stress and kill nursery plants. When sharing rooms, humidity domes will almost always be needed, as vegetative and mother plants are generally kept at lower humidity than nursery plants require.

Cloning Racks

When designing your nursery space, use multi-tier cloning racks made of high-quality materials like powder coated stainless-steel that can withstand damp growing conditions.

Our cloning racks, for example, feature 4-tiers of food-grade HIPS trays designed to fit 10×20 flats. This allows you to grow between 1,200-2,000 clones per rack.

Nursery Lighting

Cannabis utilizes the various wavelengths of the color spectrum differently throughout its grow cycle. Blue is particularly useful for young plants as it helps establish the root system, prevents stretching, and helps develop the plant’s structure. Red light is primarily used for photosynthesis which is required for the plant to grow.

Because they are inexpensive, some growers use fluorescent lights in their clone rooms and nurseries. More growers are beginning to use LEDs which are becoming increasingly more affordable, are more energy efficient, and provide superior control of spectrum.

Seedlings do well with prolonged exposure to light. Most growers will keep lights on in the nursery for 18-24 hours. However, pay attention to how much heat lighting fixtures put off. Seedlings are particularly vulnerable to heat burn and drying out if they are exposed to lights that are too strong.

What’s the Best Temperature and Humidity for Seedlings?

The ideal climate for cannabis seedlings and clones varies by cultivator, and some cultivators have special “recipes” that elicit certain growth response, but the industry standard usually falls somewhere in the range of 65-80% humidity and 70-85°F lights on / 65-75°F lights off.

At this stage, plants are too young to have established their root systems. This means that their water and nutrient uptake will be significantly lower than that of a mature plant. Young plants can help supplement this by minimizing transpiration and may even intake water through their leaves at slightly higher humidities. Then, as they grow, you can introduce them to lower RH levels.

Transplanting From the Nursery to Veg

Typically, seedlings are ready to leave the nursery 2-3 weeks after they are transplanted. Plants are usually a little stressed and may show signs of of that the first few days after being transferred Don’t be overly concerned about minor signs of stress, but if your plants are showing deep stress, try bumping up the humidity for a day or two, or turning down the light levels slightly, to harden them off. But a little bit of stress isn’t necessarily a bad thing. In fact, stressing your plants can actually help make them stronger when carefully managed.

When moving your seedlings to veg, transplant them into a properly-sized container. This will depend on your grow media and how many times you plan on transplanting. If you only plan on up-planting once, then be mindful of nutrient and water waste.

Don’t overly coddle your seedlings and nursery plants. Start with 10-25% more plants than you will ultimately bring to flower and cull the weaklings before moving them to the veg room. This will create stronger mature plants, capable of producing a larger yield.

Ready to Start Planning Your Nursery Room Design?

Surna Cultivation Technologies can provide everything you need to bring your operation to life including architectural design and floor plans, MEP engineering, benches and grow racks, LED lights, and more. Contact us today to discuss your goals.