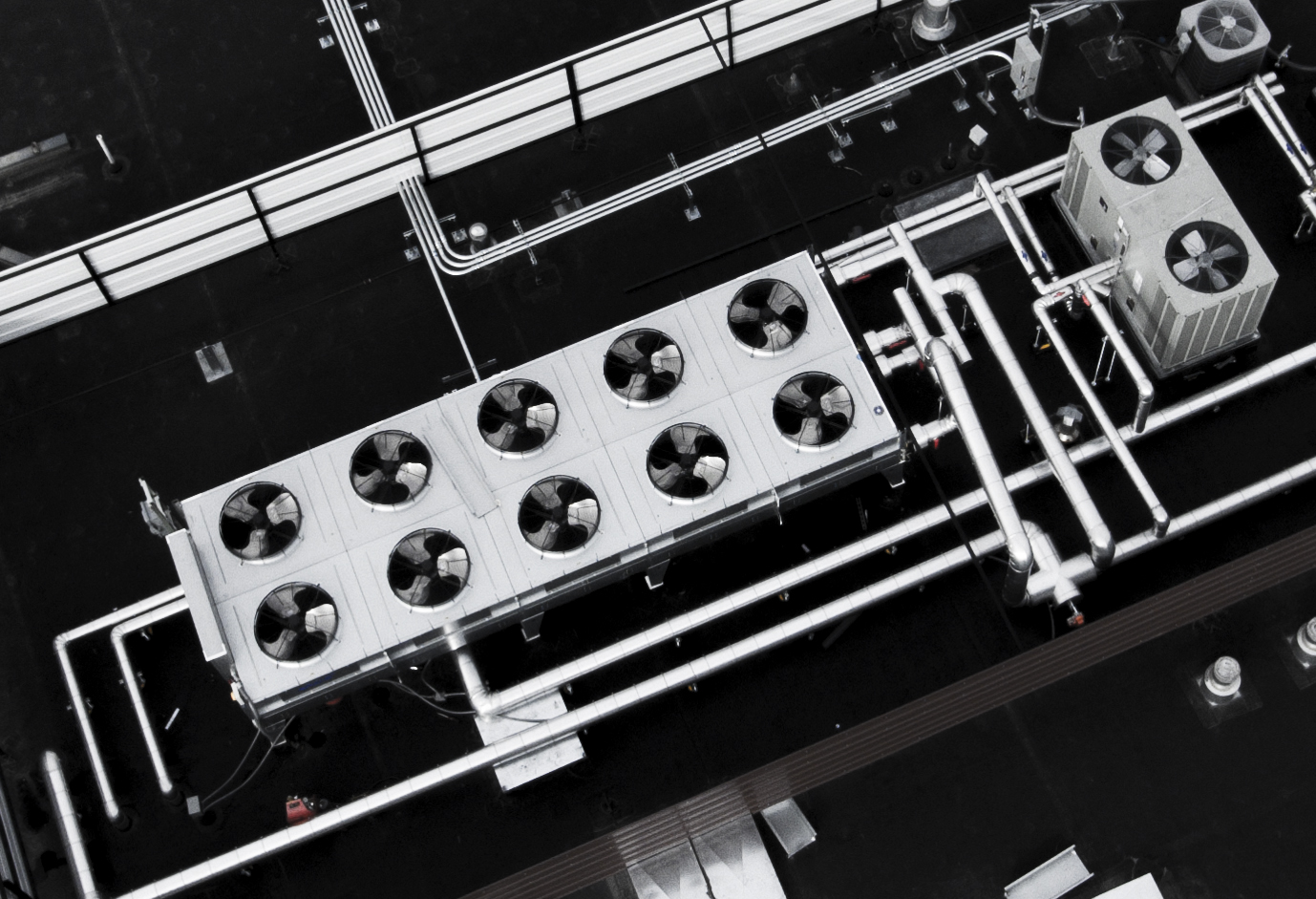

How Much Does it Cost to Start an Indoor Cannabis Grow?

How much will it cost to start an indoor cannabis operation? There are many variables to consider that can drastically affect price including equipment, size, location, and more. We’ll dive into what these variables are and present an example of what a start-up cost for a cannabis facility could look like. We’ll also look at some of the tools you can use to help you shape your budget.