In 2022, cannabis sales exceeded $30 billion in the United States. And with more states adopting cannabis legalization laws each year, the industry is continuing to grow. Naturally, Americans have viewed the market as a modern day gold rush and have sought to start their own indoor cannabis grow operations. But everyone with the vision of opening a cannabis grow will ask the same important question: how much will it cost?

Especially as more operators come online, the race to profitability is top of mind. Facing increased competition and uncertain economic conditions, investors are being more cautious. Operators seeking financial backing must be able to present a solid business plan and a clear path to profitability if they hope to win over investors.

Let’s look at some of the major components of your indoor farm startup and how much you may be looking at spending.

Average Startup Cost of an Indoor Cannabis Grow

This is usually one of the first questions our clients ask, but there are many variables that could drastically affect price including equipment, size, location, and more. Typically, the average cost to start up an indoor cannabis grow ranges between $325-$650 per square foot, and operating costs will also depend greatly on the decisions you make during buildout and every day after you open your doors.

Before you begin budgeting, take the time to examine the variables below and coordinate your goals with your design team. This will give you a much more accurate budget and will ensure you and your suppliers share the same expectations.

Startup Costs

Before you can begin bringing plants into your grow rooms, you will face many planning and preparation requirements. While most businesses can open their doors by simply renting a space and moving supplies and equipment in, growing cannabis indoors requires significant design coordination.

Keep in mind that the scale of your facility will make a significant difference at every level of your buildout. Naturally, a larger space will cost more to build out, but it’s a bit more complex than that.

For example, the cost per ton of HVAC, depending on the system approach, could actually decrease with larger spaces. Certain building materials (such as metal shells) may be an inexpensive option for buildings up to a certain size, after which the cost per square foot could increase dramatically.

Other space utilization factors will also play a key role in determining your start up costs. This includes the percentage of the facility that will be dedicated to grow rooms, or if you will incorporate extraction rooms or other specialty rooms.

Design and Engineering

Even if you opt to purchase an existing building to retrofit for cultivation, you will still need the help of architects and engineers to ensure the building is equipped for your specific needs. This includes creating an interior layout conducive to supporting agriculture, completing utility upgrades if necessary, and designing an HVAC system meant for cultivation.

Typical commercial building mechanical systems are suitable for “comfort” cooling, meaning they can keep temperatures at a level that is comfortable for the humans who use the space. However, most of these systems are not powerful enough for the high-humidity environments that cannabis requires.

The abundance of lighting generally makes grow spaces warmer as well, which increases the load on the AC. There are many reasons why HVAC must be specially designed for cannabis applications, so check out our white paper if you’d like to learn more.

The costs of your architectural design and mechanical, electrical, and plumbing (MEP) engineering will vary depending on a number of things. Some major areas of impact include the size of your operation, the technology approach you decide to take, and which firm you choose.

Be wary of firms who underbid your project. While an initial low estimate may seem appealing, it could be a sign that a firm who isn’t familiar with indoor ag requirements is underestimating what the project will entail. And in the end, you could end up paying much more.

Pay attention to the scope of work section of the proposals you receive. Compare not only pricing between bids, but also the lists of inclusions, exclusions, and qualifications. Depending on the project, architecture and MEP design typically range between $4-$8 per square foot.

Construction / Building Modifications

If you are building your operation from the ground up, your architect will provide you with a set of building plans and your MEP engineers will provide you with mechanical, electrical and plumbing plans for permitting, at which point your general contractor (GC) will take over. Your GC will work with you to help manage the construction and buildout process.

Real estate and construction costs vary incredibly. Factors that can have influence your building costs include location, construction materials, the quality of the building, how many walls you’ll need, if you are building new or buying an existing structure, how much of the existing infrastructure you can use, and so on.

If you are retrofitting an existing structure, you will still have demolition and construction to contend with as you shape the building to your needs. Again, your architect and MEP engineers will provide your GC with their plans. You may also need to engage with structural and/or civil engineers to provide additional drawings that may be required by your municipality

Your GC will also need to coordinate closely with your engineering team and providers of specialty cultivation systems to ensure that your mechanical, electrical, irrigation and other cultivation specific systems are properly coordinated and incorporated.

Construction costs are incredibly hard to estimate without nailing down many details of the project first. Even variations as seemingly minor as insulation material can have a substantial impact on your costs.

HVAC Equipment

You may be surprised by just how many HVAC technology options are available. From chilled water systems, to VRF, to packaged cooling and dehumidification, there is a wide variety of approaches your mechanical engineer can take.

When selecting your equipment, it’s important to remember that not only will the price tag of your system vary, but so will your costs of operation. Different systems will offer different levels of energy efficiencies depending on the approach, availability of utilities, the scale and location of your operation, and beyond.

One important component of developing an accurate HVAC budget is understanding what your goal setpoints will be. Knowing the specific temperature, humidity, and VPD ranges you want to achieve throughout the grow cycle will be key for your design team to supply you with an appropriate solution, and important to helping estimate annual energy costs. Your desired parameters will also greatly affect the cost of your HVAC system.

Having established just how greatly pricing can change depending on the project, for growers who are simply looking for a ballpark number, most cultivation-specific HVAC systems range between $50-$150 per square foot of canopy before taking installation or controls into consideration.

Controls and Automation for Cannabis Climates

Irrigation, CO2 delivery and ventilation, fire systems, lighting, and HVAC systems must all be controlled somehow. The more sophisticated the controls, the more expensive the initial investment – although you may also save on operating costs.

Don’t worry – you have options! Some controls accomplish basic tasks like turning equipment on and off or recording temperature. Usually, these can be bought as a plug-and-play .

And there are also custom solutions in which you get to decide which bells and whistles you need. It all depends on how sophisticated the equipment you’re controlling is, how precise you want things to run, and what kind of data you want to gather.

Depending on your requirements, most controls and automation systems range between $4-$16 per square foot of cultivation. This is an incredibly wide range, so be sure to discuss your options with your engineering team and controls provider early on.

Grow Room Lighting

Your lighting selections will not only impact your yields, but it will also affect your energy costs. For example, HPS lighting tends to use significantly more wattages than LEDs and give off more heat as well, which then puts extra load on the HVAC system.

However, HPS lighting tends to be slightly cheaper than LEDs. This is starting to change, as LED technology improves and manufacturing costs come down. LEDs are also eligible for rebates in many areas, which can help slightly offset your initial investment.

There are many brands available, but there are a few key factors to consider when choosing a professional grow light including spectrum, PPFD, warranty, pricing, and more. Commercial grow lighting fixtures usually cost $40-$60 per square foot of cultivation.

Grow Benches and Racking

Grow benches and racking systems are necessary for efficiently, and cleanly, organizing your plants within a grow space. Few growers keep their plants in containers directly on the floor. Doing so makes organizing and servicing plants a hassle, and it can add unnecessary hours to your labor.

Vertical grow racks are designed for cultivating on multiple tiers. Most growers will at least use a cloning rack in their nursery when the plants are small, but vertical farms continue stacking plants in veg and even flower. This drastically improves your space utilization.

Vertical racks are more expensive than basic benches, though. And adding more plants into a room means adding more lights, which means that your HVAC system will need to be able to handle those increased loads while also maintaining proper air flow.

Grow tables and vertical racks can also be configured to be stationary or mobile. A stationary grow table is usually the cheapest option, but mobile options like rolling benches and track racks make it possible to fit more plants into one room by letting you push them all to one side or another.

As mentioned, you have many options for benches and racks meant for indoor cultivation – not to mention that your irrigation method will also help determine your racking needs. Basic single-tier benches usually range between $10-12 per square foot of canopy, and prices will increase as you add options for mobility, multiple tiers, and various irrigation methods.

Water Treatment, Fertigation, and Irrigation

Having a clean, consistent supply of water is essential for growing a consistent product. Water purification allows you to remove particulates, pathogens, and debris. For this reason, many growers choose to purify their water supply before it’s introduced to their plants.

There are many water filtration options including screen filters and membrane filters, commonly called reverse osmosis (RO). You can also go beyond filtration and incorporate disinfection measures such as ultraviolet radiation (UV), and oxidizers like Ozone. Choosing the right solution is a matter of preference and budget.

Many growers automate the injection of nutrients into the water supply, a process known as fertigation. Automating this process keeps your recipe consistent and reduces labor requirements.

When it comes to delivering water and nutrients to the grow space, you have several options. The most common irrigation methods for cannabis include:

- Drip Irrigation Delivers specified amounts of water to individual plants using a timer or volume meter. Drip systems are used most commonly with a substrate such as dirt, coco fiber, or rockwool. These systems are usually comparatively inexpensive, although you may spend more on replacing soil and fertilizer.

- Hydroponic Flooding – Allows benches to be flooded with water and nutrients intermittently and then drained. This is used most commonly with rockwool cubes. Flood tables are not as expensive as aeroponic options and are a popular choice among commercial growers, although they may not be feasible in larger facilities or multi-tier operations.

- Aeroponics – Uses a similar approach to hydroponics, but instead delivers water and nutrients to the roots periodically through misting rather than through total submersion. This is arguably the most precise method for conserving water and controlling nutrient delivery.

Water treatment, fertigation, and irrigation systems costs will depend on your location and preferences. For instance, it’s common for growers to use an RO system to remove impurities from their municipal water, but some areas have such high-quality water, an RO system would be overkill.

Security Systems

While general security surveillance may be beneficial for most businesses, it is an absolute necessity for cannabis grow operators. In fact, your cultivation license requires it. Security system requirements differ from state-to-state but are generally intensive regardless of location.

No matter what is required by your state or municipality, however, you should take sufficient measures to protect your business and your staff.

Many cannabis cultivators try to camouflage their facilities, making them look like an indiscernible warehouse from the outside. Fencing, alarms, cameras, and even armed guards can all enhance your facility’s security. While it is difficult to estimate a price without knowing more specifics, cultivators should understand that the cost of the security systems will be a significant investment

Operating Costs

As mentioned already, your equipment selections will have a profound impact on your water and energy usage. For example, hand watering will have little-to-no upfront cost, but will cost more down the line in water usage and labor.

Your HVAC system and lights will play the most significant role in determining your monthly utility bills. Some systems are designed to be more energy efficient, but come with a higher price tag. Some systems are designed to be more affordable upfront, but sacrifice energy efficiency and precision. Some systems are better suited for growers in cool climates. Some are more affordable at a larger scale. The list goes on.

There are many variables that help determine which HVAC approach is best for your grow. A qualified HVAC designer will take the time to understand your desired setpoints, watering rates, lighting selection, etc. before providing you with a design.

How to Model a Grow Operation’s Financial Projections

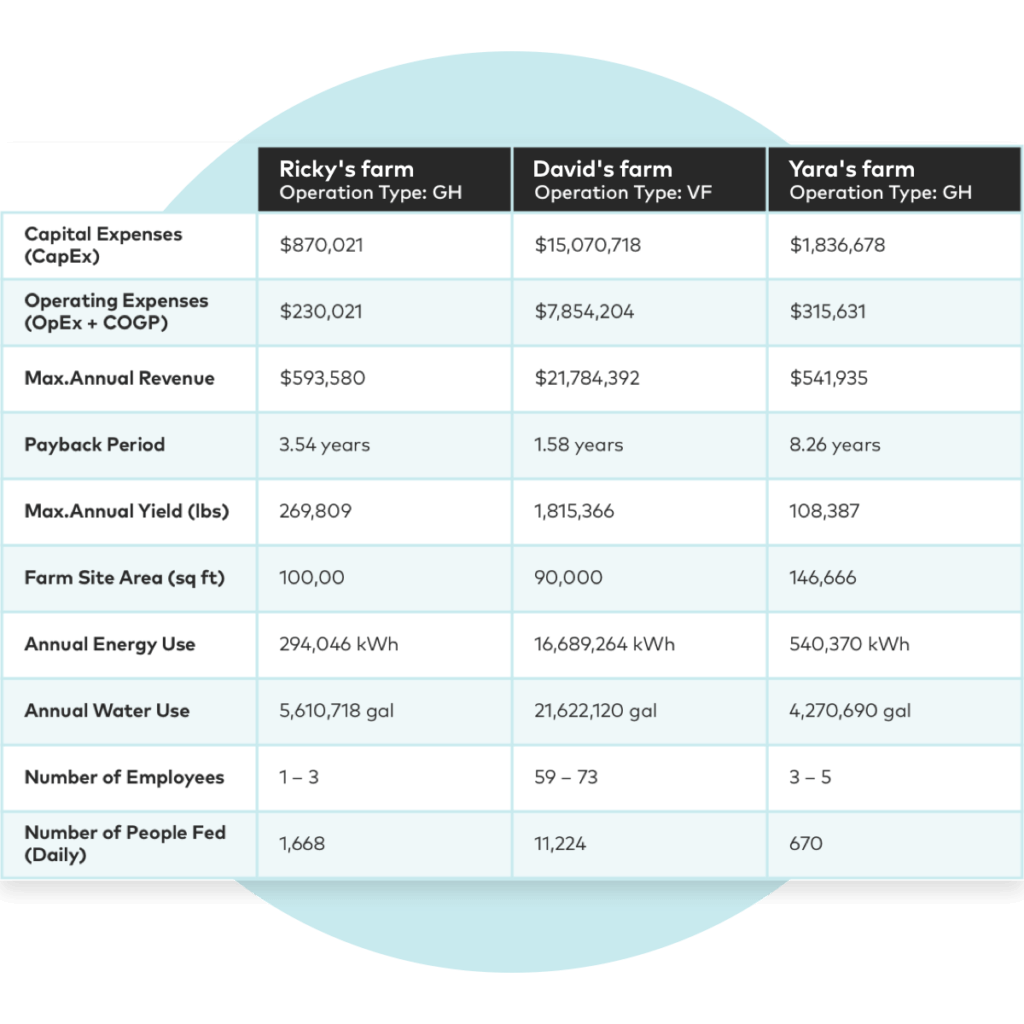

With so many variables involved, how can you begin to answer the initial question, “How much will it cost to start a cannabis grow operation?” Luckily, there is a new tool that can help get you started.

Agritecture has developed a platform that makes business modeling for controlled environment agriculture possible. With Agritecture Designer, you can generate financial projections and gain access to Agritecture’s vetted network of industry experts, including an exclusive learning module hosted by Surna’s Ian Atkins, P.E.

Although the platform currently does not offer cannabis as a specific crop selection, you can still gain insights to other indoor cultivation models, learn about best practices, and connect with experts in the field.

Start your 7-day free trial of Agritecture Designer today, and use code SURNA20 for 20% off of your membership.

Example Cannabis Cultivation Building Costs

The below estimation is intended to be used for illustrative purposes only. Because costs vary so drastically between projects, this information does not represent data from a specific client and does not represent the in-depth calculations that are necessary for permitting.

Instead, we have roughly generalized the below costs in order to provide an example of what a commercial-scale grow’s costs may look like. These figures are limited to the costs associated with the initial buildout and do not take into account variables such as licensing, marketing, labor, etc.

To understand the scope of which these costs will vary between projects, please refer to the information above (highly recommended). To obtain a more accurate estimate and proposal, please contact us below to get started.

This example is based on the following assumptions:

- 20,000 sq. ft. building

- 2,500 sq. ft. veg canopy space (single-tier)

- 10,000 sq. ft. flowering canopy space (single-tier)

Example Farm: Initial Investments

| Low-End | Middle | High-End | |

| Architectural Design and MEP Engineering ($4-$8 per square foot) |

$80,000 | $120,000 | $160,000 |

| Building ($100-$200 per square foot) |

$2,000,000 | $3,000,000 | $4,000,000 |

| Cultivation-Specific HVAC Equipment ($50-$150 per square foot of cultivation) |

$625,000 | $1,250,000 | $1,875,000 |

| Benching ($10-$12 per square foot of cultivation) |

$125,000 | $137,500 | $150,000 |

| Lighting ($40-$60 per square foot of cultivation) |

$500,000 | $625,000 | $750,000 |

| Controls ($4-$16 per square foot of cultivation) |

$50,000 | $125,000 | $200,000 |

| Other Systems/Construction and Installation ($150-$300 per square foot) |

$3,000,000 | $4,500,000 | $6,000,000 |

| Total Startup Costs* | $6,380,000 | $9,757,500 | $13,135,000 |

Example Farm: Annual Operating Costs – Energy, Water & Maintenance

| Cost of Electricity (Lighting) 480W veg LEDs @ 18/6 schedule 680W flower LEDs @ 12/12 schedule Cost of electricity = $0.16/kWh | $378,000 |

| Cost of Electricity (HVAC/Other) Assumes lighting accounts for 43% of electrical usage | $587,500 |

| Water Consumption Assumes 0.25 gal daily irrigation volume per SF in flower and 0.15 gal per SF in veg Cost of water = $0.02/gal Assumes 1:1 RO ratio | $38,000 |

| Facility & Systems Maintenance | $60,000 |

| Total Operating Costs – Energy, Water & Maintenance* | $1,063,500 |

*This illustrative example does not account for the full scope of business operations including taxes, licensing, lab testing, packaging and transport, labor and administration, marketing and distribution, consumables (nutrients, trellis netting, etc.), fluctuations in utility costs, various financing options, etc.