When it comes to growing indoors, there are a few different ways to store and organize your plants. One method rising in popularity is to use vertical grow racks. Vertical grow racks, also known as “vertical racking,” allow you to stack plants in small areas, maximizing the square footage you can use for cultivation.

What are Vertical Farming Racks?

A vertical farming rack, or “grow rack,” is a type of shelving system you can use to store and cultivate plants. Vertical grow racks can allow you to grow a variety of cultivars while providing ample space for LED lighting, airflow, and room to access the plants.

Vertical grow racks are perfect for growers who have space limitations in their facility, or to increase the number of plants that can be grown per square foot by taking advantage of the vertical space in the room.

If you are considering purchasing vertical grow equipment, there are a few things to keep in mind:

- Size: First, make sure to account for the size of your room, the number of plants each rack will hold, and accessibility. Depending on your budget and scale, there are mobile vertical farming systems that can maximize small spaces even more by forming moveable aisles.

- Type of plants: Not all plants do well in vertical racks. Make sure to research which ones would be best for your setup. For example, fruit trees, sunflowers, and other tall crops are not suitable for growing vertically. However, cannabis, leafy greens, strawberries, basil, carrots, etc. can thrive in vertical grow systems.

- Lighting: Some vertical grow racks come with built-in lighting, but there are many LED options that can be easily mounted within each tier.

- Watering: Vertical farm racks can be outfitted for various irrigation approaches. Expanded metal trays should suffice for growers using traditional soil media, but other options exist for ebb and flow hydroponics or even aeroponics.

With these things in mind, vertical grow racks can be a great way to save space and cultivate your plants.

What are Tiers?

A “tier” is simply a level or shelf on which you can grow plants. Using multiple tiers can increase your growing space without taking up any additional floor space. Vertical systems are perfect for small grow rooms, as they allow you to make the most of the space you have. The number of tiers you need will depend on the amount of space you have and the number of plants you want to grow.

The Benefits of Using a Vertical Grow Rack

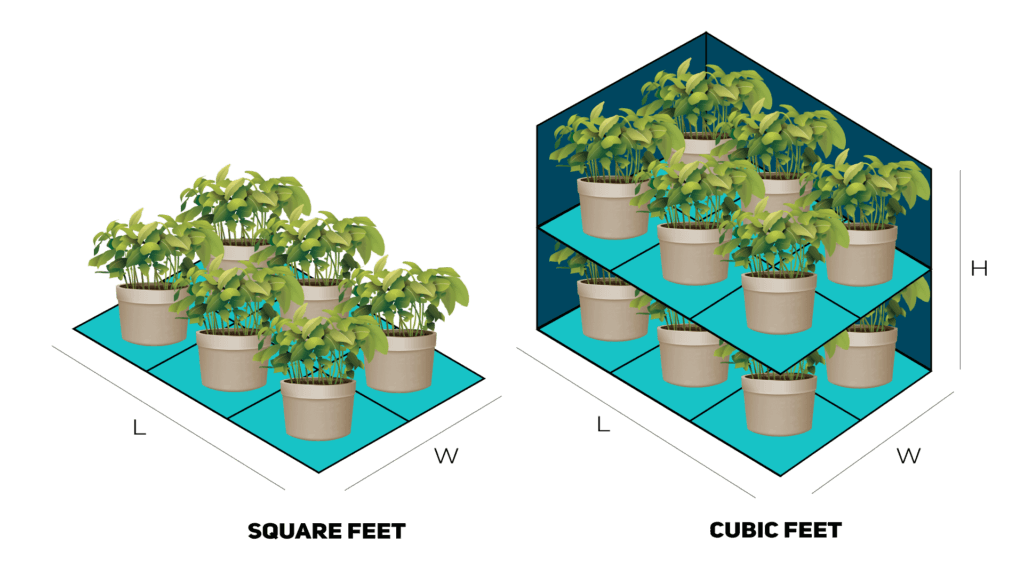

The main benefit to using vertical farming systems as opposed to single-tier benches is that indoor growers can maximize the plant canopy. The difference is best illustrated by comparing cubic feet rather than square feet of cultivation space.

Square feet = Length x Width

Cubic feet = Length x Width x Height

Let’s look at two common examples, simplified.

8 ft Height Increments

It is common for cannabis cultivators growing in multiple tiers to space their shelving heights between 8 and 12 feet apart.

Growing on a single tier, a 100 sq ft footprint would provide 800 cubic feet of cultivation space.

10 x 10 x 8 = 800 cu ft

Growing on two-tiers, a 100 sq ft footprint would provide 1,600 cubic feet of cultivation space.

10 x 10 x (8+8) = 1,600 cu ft

| Footprint Size | 100 sq ft | 100 sq ft |

| Height Between Tiers | n/a | 8 ft |

| Number of Tiers | 1 | 2 |

| Total Rack Height | 8 ft | 16 ft |

| Cultivation Space | 800 cu ft | 1,600 cu ft |

2 ft Height Increments

It is common for tiers of leafy greens to be spaced about 2 feet apart.

Growing on a single tier, a 100 sq ft footprint would provide 800 cubic feet of cultivation space.

10 x 10 x 2 = 200 cu ft

Growing on four-tiers, a 100 sq ft footprint would provide 1,600 cubic feet of cultivation space.

10 x 10 x (2×8) = 1,600 cu ft

| Footprint Size | 100 sq ft | 100 sq ft |

| Height Between Tiers | n/a | 2 ft |

| Number of Tiers | 1 | 8 |

| Total Rack Height | 2 ft | 16 ft |

| Cultivation Space | 200 cu ft | 1,600 cu ft |

As you can see, the cultivation space will continue to increase as you add more tiers without increasing the square footage. The height increments between tiers will also have an effect, and the height requirements for each level will depend on what you plan to grow, as some plants are taller than others.

Types of Racking for Indoor Agriculture

Vertical grow racks come in various sizes. You can also find them with different numbers of tiers.

When choosing a vertical grow rack, select one made from high-quality materials that are resistant to the warm, wet, and sometimes dirty nature of indoor horticulture. Choosing high-quality materials will help ensure that it lasts for many years. Additionally, look for a rack that has been powder coated; this will help prevent rust and other corrosion.

There are two main types of racking equipment: stationary and mobile racks.

Stationary Racks

Stationary racks are shelves designed for cultivation. While stationary racks are great for small spaces, they can’t be moved around easily. You will also need to incorporate aisleways in your layout so that personnel can access the plants properly, which will take up some of your square footage. These tend to be the least expensive racking systems, however.

Mobile Racks

Mobile racks are a direct chain-driven system that allows you to turn an easy-to-handle crank to push the racks from side to side to create aisles as needed while maximizing the horizontal space.

Other Types of Vertical Farming Racks

Stackable

Stackable racks are a custom multi-tier option. The number of shelves or tiers will be limited only by the room’s height.

Cloning racks

Cloning racks hold grow lights closer to the plants for increased light exposure, giving greater control over plant development. Surna provides cloning rack solutions that allow up to 4-tiers that can support 1,200-2,000 clones per rack.

Drying racks

Drying racks allow cultivators to hang cannabis and herbs vertically, making it easier to dry them thoroughly. Eliminating water is especially important for cannabis plants, as improper drying can result in mold or mildew. Drying racks also help preserve the buds’ quality by preventing them from being crushed during the drying process.

How to Choose the Right Rack for Your Indoor Grow?

When choosing a vertical grow rack for your cannabis plants, flowers, herbs, fruits, or vegetables, keep a few things in mind. Taking the time to design your facility footprint will save you a tremendous amount of stress in the future.

Because of this, we advise consulting with a company experienced in architectural design and MEP engineering specific to indoor agriculture. Your architect and racking supplier can coordinate their designs to optimize your room sizes and rack layouts.

Here are some things to consider when selecting the right vertical grow rack for your needs.

Size

You’ll also want to consider the depth and width of the rack, as this will affect the amount of grow space you have for plant pots or containers.

Number of Tiers

Once you’ve determined the footprint of your racking equipment, you’ll need to decide how many shelves or tiers you’ll need. Remember that some plants grow taller than others and will require higher vertical growing spaces than others. For example, you can fit more tiers per square foot growing lettuce than you could growing cannabis.

You must also take into account the effect that growing in multiple tiers will have on your temperature, dehumidification, ventilation and airflow, and irrigation needs. Adding more plants to a space will increase your HVAC loads, and it can make it trickier to keep a homogenous environment that is vital to consistent plant quality. We have developed a vertical climate solution for this called StrataAir.

Material

You’ll want to choose a material that won’t corrode or rot. Look for a rack that’s made from stainless steel, powder-coated metal, or another non-corrosive material.

Cost

Finally, make sure that the price of your vertical farming rack is within your budget, and weigh the costs and benefits to best suit your business’ long term goals.

Mobile racks are more expensive, but they help maximize your space more than stationary racks. There are also various options for trays and irrigation approaches that will affect the price of your equipment as well.

Additional Considerations for Vertical Farming Equipment

Proper lighting

When growing indoors, you must provide artificial lighting for your plants to photosynthesize properly.

However, it’s important to note that HPS lights require a fairly large mounting height above the canopy so as not to burn the plants. Instead, consider LED lights. These produce far less heat, and can be safely mounted 1-4 feet above the canopy.

Needs of specific crop types

While many plants can be grown vertically, you should understand which ones are best-suited to the task. First, look for plants with a naturally compact or columnar growth habit, such as tomatoes, cucumbers, and peppers. These plants will require less training and support than sprawling varieties. Also, consider the size of your space when choosing crops. Taller plants like pole beans and indeterminate tomatoes will need more vertical real estate than compact herbs or salad greens.

Certain plants, such as fruit trees, grains, or sunflowers, are difficult or even impossible to grow in a vertical application.

Irrigation

Vertical grow racks are a great way to increase the number of plants you can grow indoors. By using vertical space, you can save floor space and increase yields per harvest. First, however, it is essential to verify that your plants receive enough water when grown in a vertical rack. It goes without saying, but if your plants are not adequately watered, they will not be able to photosynthesize correctly and will eventually die.

One way to ensure that your plants receive enough water is to use a drip irrigation system. This system slowly drips water onto the plants, providing them with a constant supply. Another option is a misting system, giving the plants a fine water mist. Some racks come with ebb and flow irrigation trays so you can grow hydroponically.

There are many different vertical grow racks available, be sure to do your research before purchasing one.

Conclusion

Surna is here to help you choose the perfect configuration for your grow operation! An expert representative will work with you to assess your specific needs and recommend the best option for you. Contact us today to learn more.