Sealed grow room environments will require heat to be removed, even during the winter months. Yes, heat needs to be added, but a cooling system will help keep a balanced climate. Facilities located in cooler regions such as Canada, Alaska, North Dakota, Wyoming, etc., have the option to take advantage of the already-cold outside air for what is called “free cooling” with the incorporation of a Dry Cooler or Cooling Tower.

So what are these technologies, how do they work, and what makes them different?

Refrigeration

Let’s start with a quick explanation of how refrigeration typically works. Typically, refrigerant flows through a compressor, which raises the pressure and temperature of the refrigerant in vapor form. The refrigerant vapor then cools and condenses into a liquid. Then the liquid refrigerant is allowed to expand and this expansion drops the temperature below its starting temperature. Remember, the process of cooling actually involves removing heat, not adding cool. This process is called the vapor-compression refrigeration cycle. To learn more read this article.

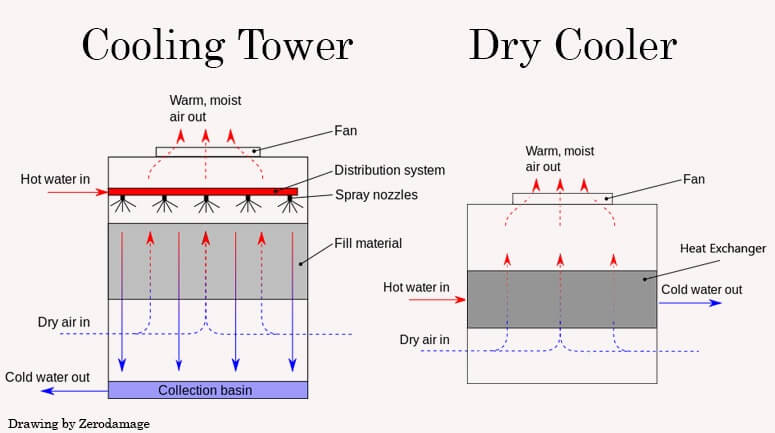

However, with Cooling Towers and Dry Coolers, a compressor is not necessary to reject heat. Instead, fans are used to move air over a heat exchanger, creating a more efficient means of providing cooling.

Cooling Towers

Cooling Towers use evaporation to provide cooling. But don’t worry, the cooling tower is located outside and will not add extra humidity to your grow room. Cooling Towers are commonly used to cool nuclear power plants, so they are capable of processing large amounts of heat.

In a Cooling Tower, hot water is sprayed on a medium in order to spread it out. From there, outside air, which is cooler than the water, mixes with the water and causes evaporation. For a better explanation, watch this video.

Because of the evaporation, Cooling Towers require continuous water refills to maintain an appropriate water level.

Dry Coolers

The main difference between Dry Coolers and Cooling Towers is that Dry Coolers do not require water. Instead, air is blown over a heat exchanger in order to remove the heat from the liquid in the system.

Dry Bulb vs Wet Bulb

In order for Cooling Towers and Dry Coolers to work, the temperature of the water in the system needs to be hotter than the air temperature. However, air temperature has two parts: Dry Bulb temperature and Wet Bulb temperature.

Dry Bulb temperature is the temperature thermometers read. This is the temperature referred to when talking about how hot it is outside.

Wet Bulb temperature, on the other hand, is the temperature a thermometer would read if it was wet and had air moving over it. Wet Bulb temperature is affected by the humidity in the air and will always be lower than the Dry Bulb temperature.

Cooling Towers work as long as the Wet Bulb temperature is lower than the temperature of the liquid running through it. When talking about cooling a Surna Reflector, the water to be cooled clocks in around 120 degrees F. So the wet-bulb temperature only needs to be around 85 degrees F (or lower) in order to work properly – a condition that is achievable in most of the country throughout the year.

Dry Coolers work off the Dry Bulb temperature, meaning the outdoor temperature needs to be lower than what Cooling Towers require for effective heat transfer. As such, Dry Coolers are not as effective year-round as Cooling Towers.

However, Dry Coolers are easier to maintain because the water is not exposed to air (closed loop) and they do not require water testing . Cooling Towers are susceptible to degradation through fouling (getting clogged up), scaling (water-deposit build-ups) corrosion (gradual breakdown due to the environment), and require testing for the prevention of Legionnaire’s disease.

Overall, depending on the climate in which you live, Dry Coolers and Cooling Towers can provide an efficient and sustainable way to cool your garden, especially in combination with Surna Reflectors.