At Surna, we talk a lot about creating efficient cannabis cultivation facilities. Efficiency is key on many levels within a grow, consuming less energy, achieving the highest yield possible, but the most significant reason to strive for an efficient cultivation facility is to maximize profits. As the industry grows and matures, competition will increase and the best way to combat rising competition is to tighten up your procedures and create the most efficient grow possible, allowing you to produce higher yields for less money.

Here are some of the top ways you can reduce inputs and increase outputs within your grow:

Don’t waste light

Every drop of light that is produced costs money in the form of electricity. Only light that strikes the plant canopy helps plants grow, the rest is wasted. Think of it this way: what if every time you filled up your car with gas, you spilled 20% of the gas on the ground. Now, imagine you own a trucking company that does this. The amount of wasted gas and money would be enormous. The same can be said for wasted light that ends up on walls and in aisles instead of on the plants in grow rooms.

Stop using single-ended HPS bulbs

Single-ended HPS bulbs are the least efficient of all the bulbs on the market. Simply switching to double-ended HPS bulbs can result in a 30% increase in light output, using the same amount of electricity.

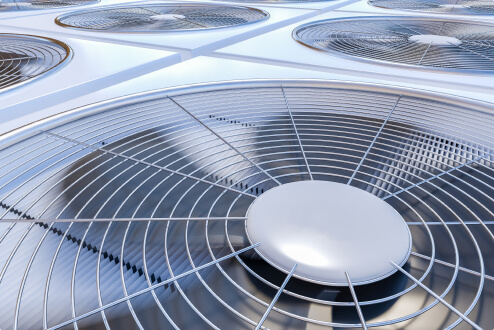

Use process cooling

There are two types of cooling: process and comfort. Comfort cooling is designed to keep humans comfortable. It is designed for minimal load and to only run during the warm, summer months. Process cooling is designed for high-heat environments. It is meant to remove large amounts of heat, year-round. Using the correct type of cooling will result in higher efficiencies and longer lasting equipment.

Use free cooling when possible

In some areas, it is possible to use outdoor temperatures to cool your grow. If you live in one of these cooler climates, take advantage of it. Using Dry Coolers, cold air can be blown over a heat exchanger without the use of a compressor, resulting in free cooling during cold months. Data centers use dry coolers extensively to lower their electricity usage.

Implement hydroponics

Using hydroponics means you don’t have to pay to ship growing mediums to your facility, or to dispose of them at the end of a grow cycle. With hydroponics, the only input is water and nutrients. Additionally, hydroponics can result in higher yields, increasing profits further.

Resist bringing in outside air

Anytime air exchanged for outside air, any CO2 that has been added is wasted. However, if you absolutely insist on bringing in outside air, make sure to only do so when the outside air is the proper temperature and humidity level. If humid air is brought into the facility, dehumidification equipment has to work extra hard to remove the excess humidity, same goes for air that is the wrong temperature. Humid air can also lead to problems with mold, potentially ruining an entire crop.

Sanitize air

Sanitize air

Sanitizing the air in a grow room can have a huge impact on the final crop. Air sanitation prevents pests, pathogens and mold from spreading within a room by destroying the spores before they have a chance to cause more damage. Air sanitation allows for a clean grow that results in a sellable product that passes lab testing.

Don’t spill water

Ignoring the fact that all spilled water is wasted water, spilling water in a grow room costs a lot of money. Grow rooms are kept at a certain humidity level and every drop of water that enters a room affects this humidity level. When excess water is not drained away from spills, the dehumidification equipment has to work harder to remove it and restore the desired humidity level. This leads to added energy consumption and can degrade equipment faster.

Treat and reuse condensation water

Water reclaimed from air handler and dehumidifier condensation lines can be reused to water plants, simply pH and UV sterilize it. Every gallon of condensate water can save up to 5 gallons of fresh water, leading to substantial savings.

Stay on schedule

Creating a schedule for your cultivation facility and sticking to it is highly important for creating an efficient operation. Every day your Flower Rooms sit empty are lost production days. The faster you can turn over a room after harvest, the more harvests you can have per year, increasing your overall yields and profits for the year.

Have a capable grower

Above all, a capable grower who knows what is going on inside the facility and how to handle it is essential to a successful and efficient cannabis cultivation facility. A lousy grower can turn even the best equipped grows into money-losing pits while a great grower can make even the worst set-up produce high yields. Producing cannabis is what growers do best, so make sure you have the best grower you can find.