The following piece provides a technical insight into HVAC technologies relevant to controlled environment agriculture (CEA). This was written by Surna Cultivation Technologies’ Ian Atkins, P.E. Mr. Atkins is a licensed engineer who specializes in HVACD system design for cannabis grow rooms.

The following piece provides a technical insight into HVAC technologies relevant to controlled environment agriculture (CEA). This was written by Surna Cultivation Technologies’ Ian Atkins, P.E. Mr. Atkins is a licensed engineer who specializes in HVACD system design for cannabis grow rooms.

Mr. Atkins will be joining a panel discussing “HVAC – What’s Right For Your Grow” on March 1, 2022 at Indoor Ag-Con Las Vegas.

The Myth About Dehumidifiers

You may have at one point heard that dehumidifiers are inefficient because they add heat to the grow room, which then must be removed by the cooling system.

It is true that dehumidifiers add heat to a grow room when they run. And this heat from the dehumidifiers increases the heat load in the room that needs to be removed by the air conditioning system (AC).

But, it’s not true that using dehumidifiers in combination with a “decoupled” cooling system is inefficient compared to the alternative of reheat in an “integrated” system; even reheat that is “free” from hot gas reheat or heat recovery chillers.

The topic of whether integrated systems are more efficient can easily spiral out of control. It can turn into an endless cycle of energy modeling of specific pieces of equipment or systems.

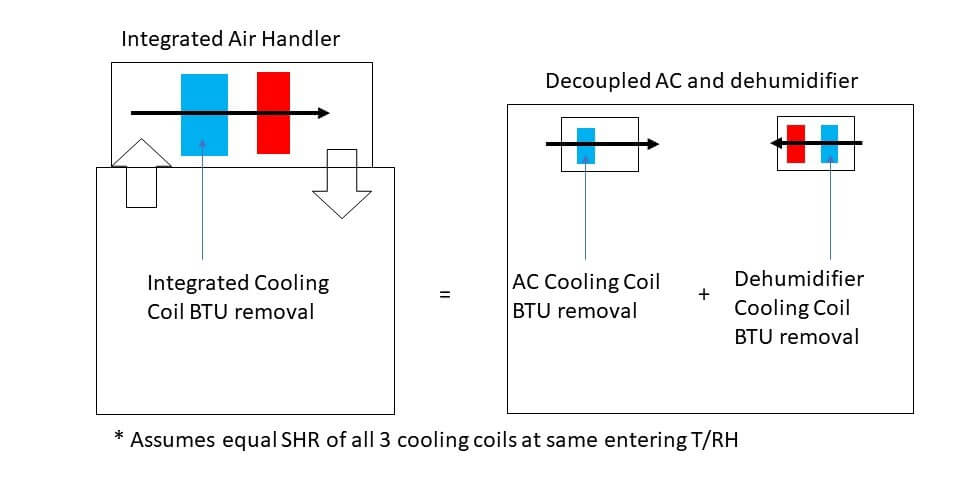

I’ve realized that there is a simple way to look at these two types of systems in general. My assertion is that the combined energy removed from cooling coils in decoupled systems via standalone dehumidifiers and a separate cooling system is actually equal to the energy removed from a cooling coil in an integrated system, with an assumption* about the cooling coils. See figure below.

And, if the same amount of BTUs are removed from cooling coils in both system types, and the efficiency of producing the cooling effect on the coils is also the same (the EERs), then so is electrical energy use.

Defining the Assumptions

The major assumption about the cooling coils to make my assertion true, is that the cooling coils have equal sensible heat ratio (SHR) at equal entering air conditions. The cooling coils being the coils that cool and dehumidify in the integrated system, inside the dehumidifier, and in the cooling system used with the standalone dehumidifiers.

This assumption means that for each BTU removed by each cooling coil, the same amount of moisture is removed.

For example, if the coil SHR is 0.75 at a given entering temperature and RH, then for each BTU removed the cooling coils, 0.75 BTU of sensible energy and 0.25 BTU of latent energy (moisture) is removed.

The equality shown in the figure above, that the total cooling coil energy removal is equal in both system types, is true over the grow cycle.

Cooling and Dehumidification Modes

For the sake of this topic, grow rooms and the cooling and dehumidification systems serving them have two modes: cooling mode and dehumidification mode.

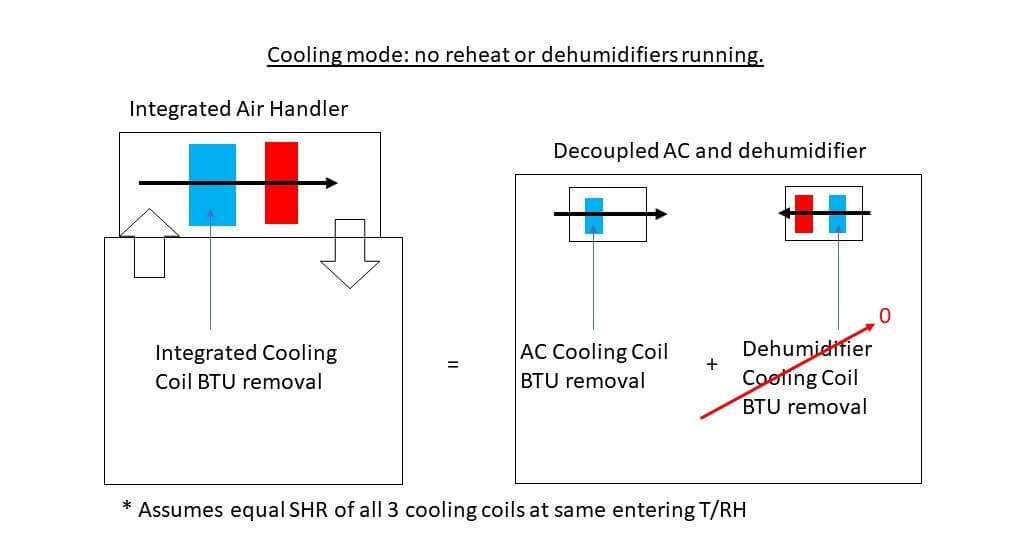

Cooling mode is where the heat load from the lights drives the air conditioner to run and the AC removes enough moisture as a byproduct of cooling to satisfy the RH setpoint (though may need humidification to keep the RH up). This mode occurs when the room sensible heat ratio is greater than or equal to the sensible heat ratio of the air conditioner, usually when the lights are on with relatively small plants and a higher T/RH setpoint (e.g. lights on in a early veg room).

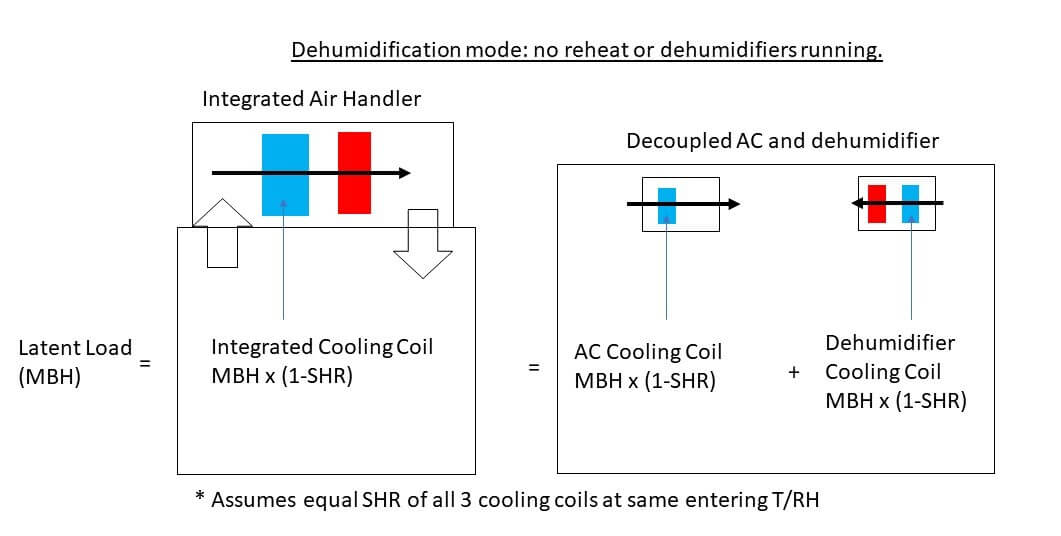

Dehumidification mode occurs when the room sensible heat ratio is less than the sensible heat ratio of the cooling coil. This is always the case during lights off and usually the case during mid and late flower with the lights on as well. Either reheat or additional dehumidifiers are needed to further dehumidify beyond what is removed as a byproduct of cooling.

So when the system is in cooling mode because the latent load is low and the lights are on, the dehumidifiers aren’t running or adding load, and the neither is the reheat coil, so both cooling systems remove the same heat load from the lights. That is, the dehumidifier cooling coil removal is zero, and the integrated system cooling coil removal is equal to the AC cooling coil removal in a decoupled system.

Latent Load and SHR

Considering Energy

Reheat energy is a separate topic. But on the topic of dehumidifiers vs reheat, dehumidifiers are free reheat, hot gas reheat, heat recovery machines. Dehumidifiers add heat to the room. But only when an analogous integrated system would also be adding reheat. So heat from dehumidifiers isn’t extra heat, it just helps the AC pull out more moisture. Integrated reheat systems can use hot gas reheat or heat recovery chillers, but gas or electric reheat will use extra energy for reheat beyond the compressor energy used by ACs and dehumidifiers.

Conclusion

My point here is not that decoupled systems are better than integrated systems. There are many good integrated systems available for grow rooms helping to condition successful facilities.

As a category though, there is no inherent inefficiency in systems with standalone dehumidifiers. Both integrated air handlers with reheat and standalone dehumidifiers operate with similar constraints and options available. Both can use different airflows and coil temps to maximize latent heat ratio and both can use the same various technologies to enhance dehumidification efficiency, such as heat pipe, wraparound air-to-air heat exchangers, and desiccant.

There are definitely good reasons to opt for integrated/reheat systems over standalone dehumidifiers, but efficiency isn’t necessarily one of them.